Brilliant results in PMMA

Transparency, rigidity, hardness and scratch resistance – these are the properties that describe this material. This is why PMMA is particularly attractive as a material for the construction industry, furniture and shop fitting, the leisure industry and as components in mobile homes. The challenge in machining is that this plastic becomes warm during processing and can begin to melt. This in turn has a negative effect on the quality of the edges and machined surfaces, resulting often in further expensive processing. Leitz offers an optimally coordinated tool programme especially for machining PMMA, which is particularly impressive in terms of quality and productivity.

The solutions from Leitz

Processing in finish-cut quality

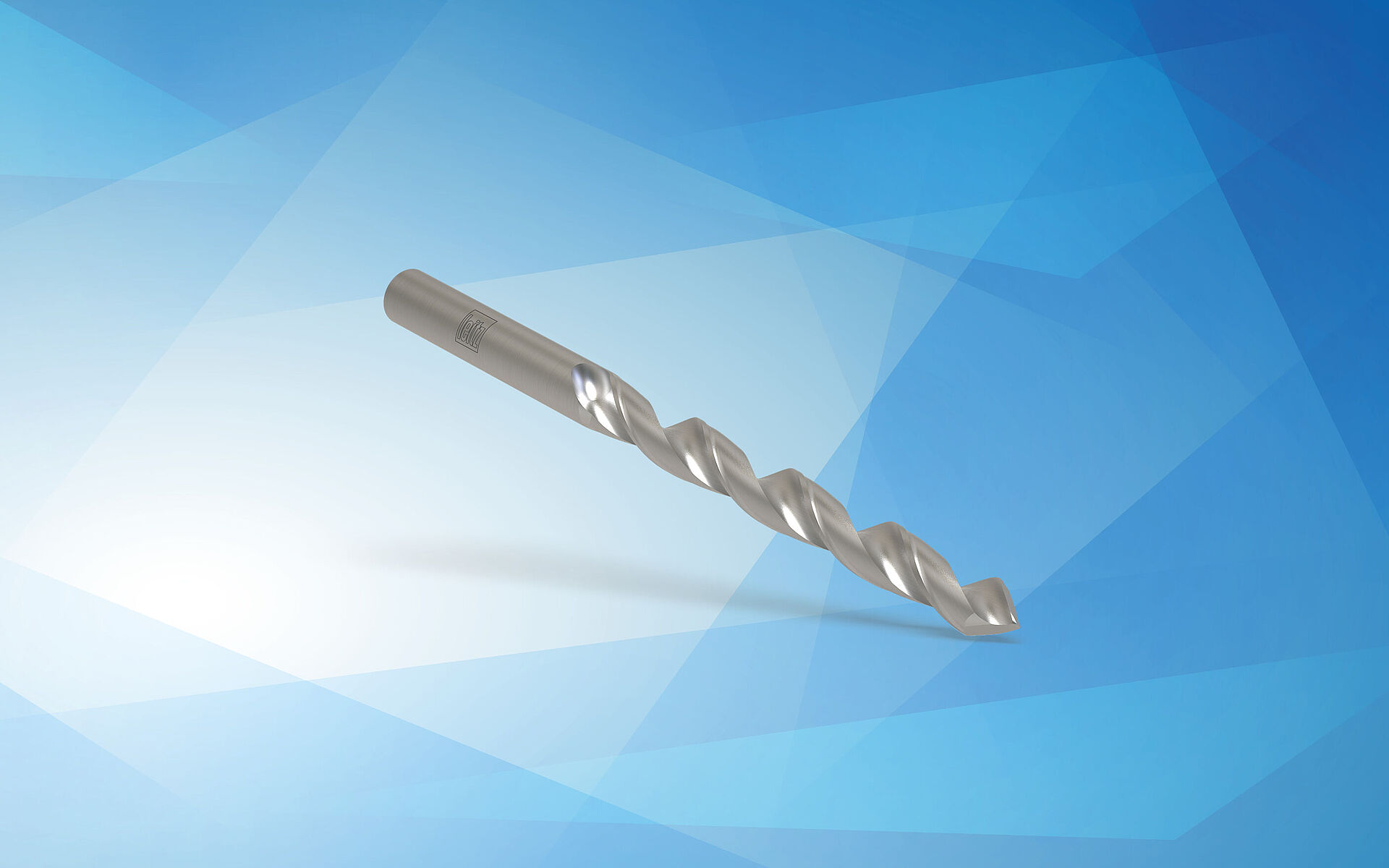

VHW spiral finishing router: The specialist for perfect edges

VHW torus router: Especially for form and contour processing

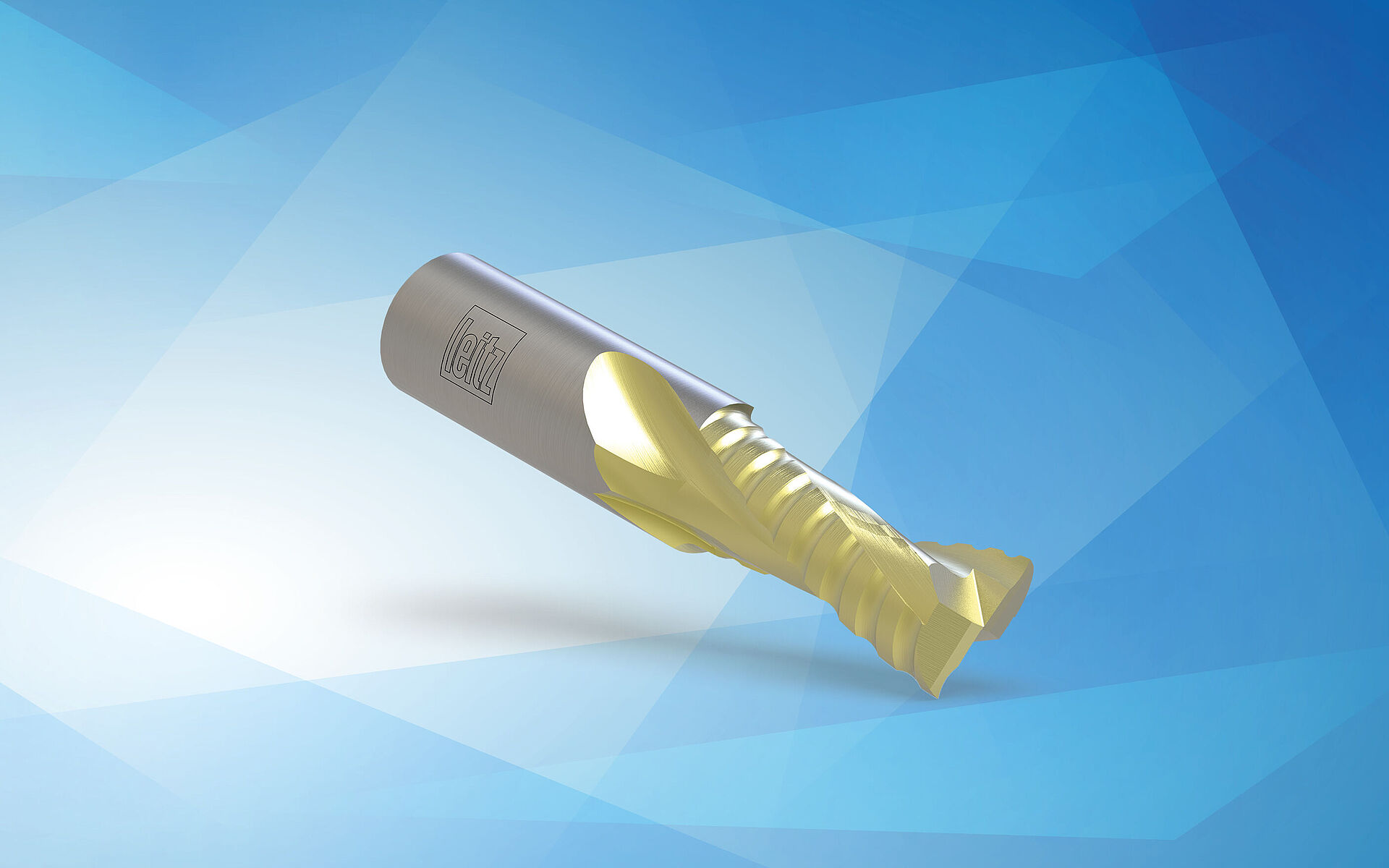

VHW Marathon spiral roughing and finishing router: The tool for sizing and grooving in roughing and finishing quality

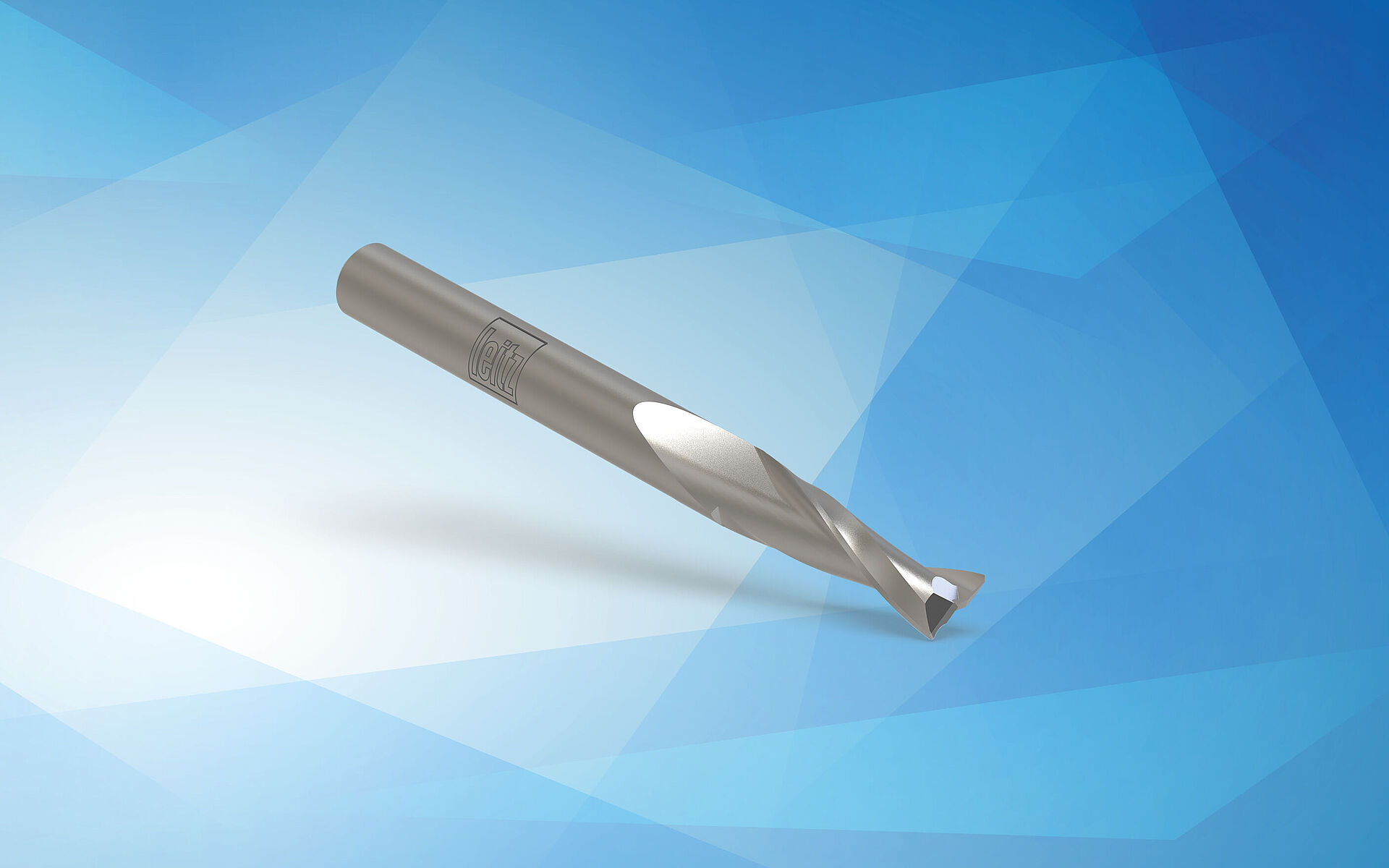

HS boring bit: Especially for through-hole bores in PMMA

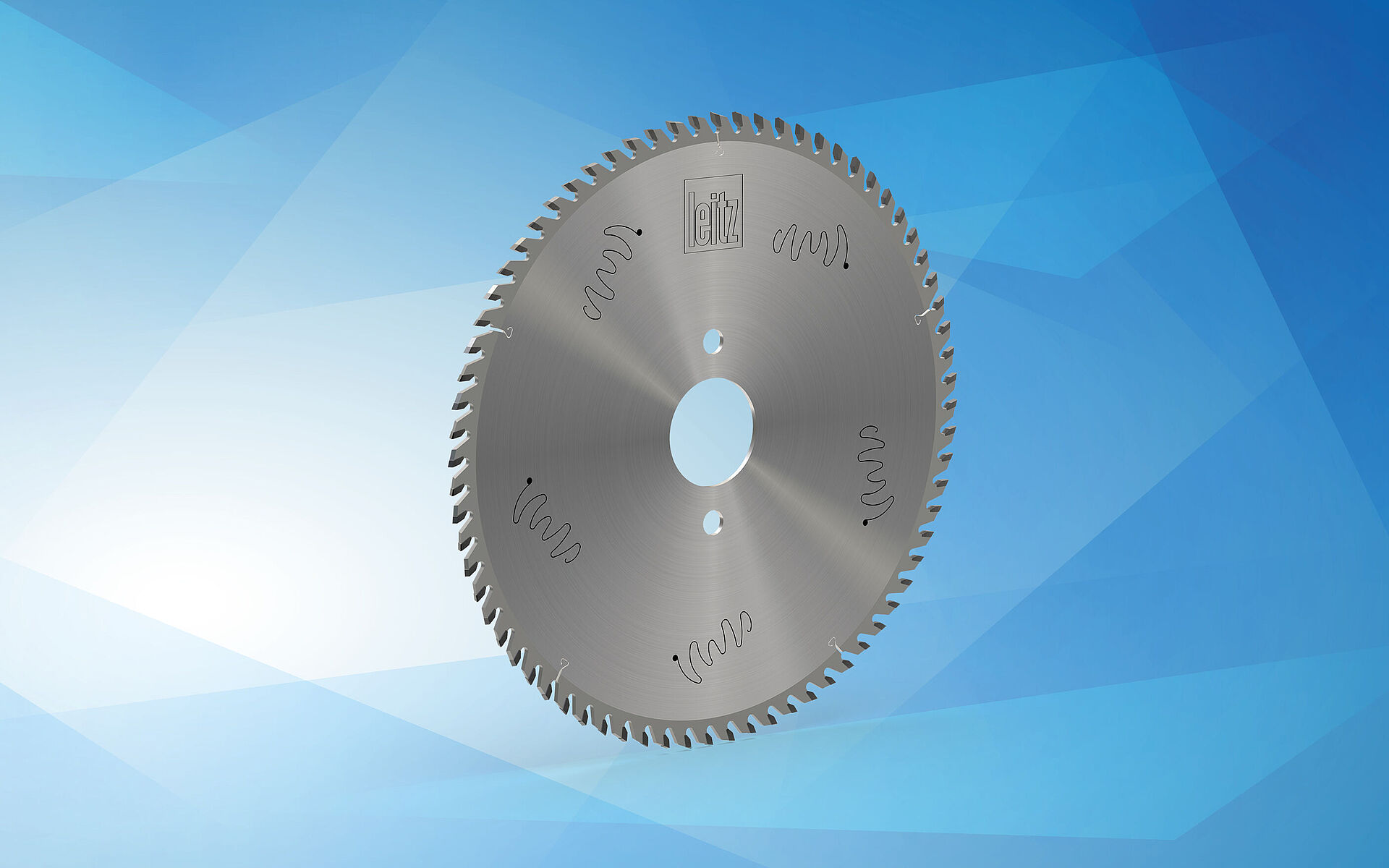

BrillianceCut HW circular sawblade: When it comes to perfect cutting areas and edges

- Perfect cut quality

- Reworking not required

- Polished groove

- Coordinated tool programme in the diameter range of 3-10 mm

- Suitable for all conventional machines

- Available from stock

- Short processing time

- Long tool life

- Perfect cutting results

- Resharpenable

- Polished cutting groove

- For form and contour processing

- Coordinated tool programme in diameter areas of 3-10 mm

- Suitable for all conventional machines

- Available from stock

VHW Marathon spiral roughing and finishing router

Productivity & Sustainability

The tool for sizing and grooving in roughing and finishing quality.

- High cutting capacity

- Long tool life

- Resharpenable

- Coordinated tool programme with diameters of 8, 10 and 12 mm

- Suitable for all conventional machines

- Available from stock

- Marathon coating

- Break-free bores

- Long tool life

- Special edge arrangement

- Multiple regrinding

- Coordinated tool programme in the diameter range of 3-10 mm

- Suitable for all conventional machines

- Available from stock

BrillianceCut HW circular sawblade

Quality & Efficiency

When it comes to perfect cutting areas and edges.

- Finish cut quality

- Reworking not required

- Long tool life

- Less noise

- Innovative tooth geometry

- Filled in laser ornaments

- Regrindable up to 20 times

- Diameter 303, 350, 380, 400 and 450 mm

- For all conventional panel sizing and sizing sawblades

- Available from stock