Tool solutions for processing insulation panels

With flexibility and productivity to deliver the ideal machining result

The applications for foamed insulation materials range from roof and facade insulation to perimeter insulation and impact sound insulation. The diversity of application types, compositions, material thicknesses or compressive strengths pose challenges to manufacturing and processing companies when it comes to achieving perfect results.

Leitz offers tool systems in its product range with class-leading performance which can be flexibly adapted to different product requirements.

Jointing & thickness calibration

Smoothness is the key

Jointing & thickness calibration

Smoothness is the key

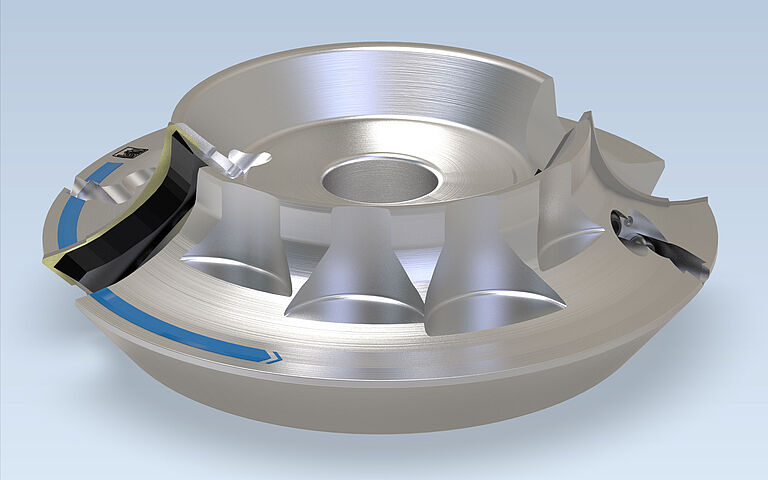

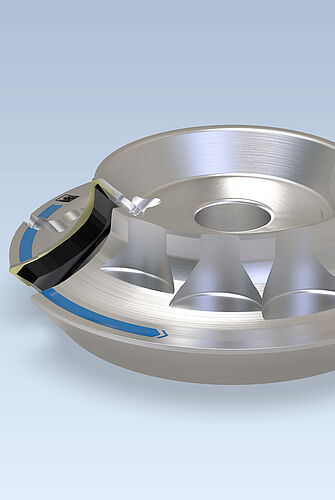

During jointing and thickness calibration, the surface and final thickness of the foam materials are defined. Different quality levels for construction and industrial applications, such as exterior insulation or bathroom design require different processing quality levels. Above all, the uniform visual structure of the end product is particularly important for further processing.

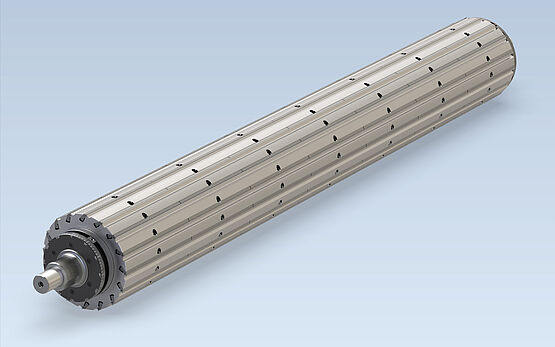

Leitz offers both individual tool solutions and standard solutions, such as the CentroFix Plus interchangeable knife system, from its extensive range of jointing and thickness tools.

Machining along & across the grain – medium cut quality

Side processing of high-density foams to perfection

Smooth edges, stepped rebates, tongue and groove connections – these profile types are the most common ways in which high density foam panels can be given corresponding profiles and shapes.

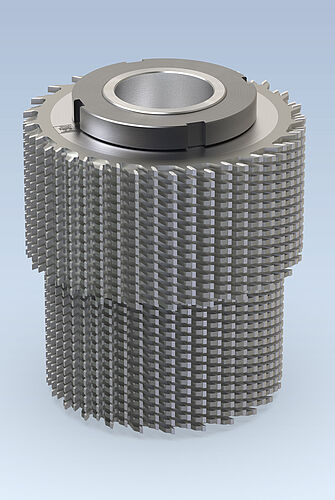

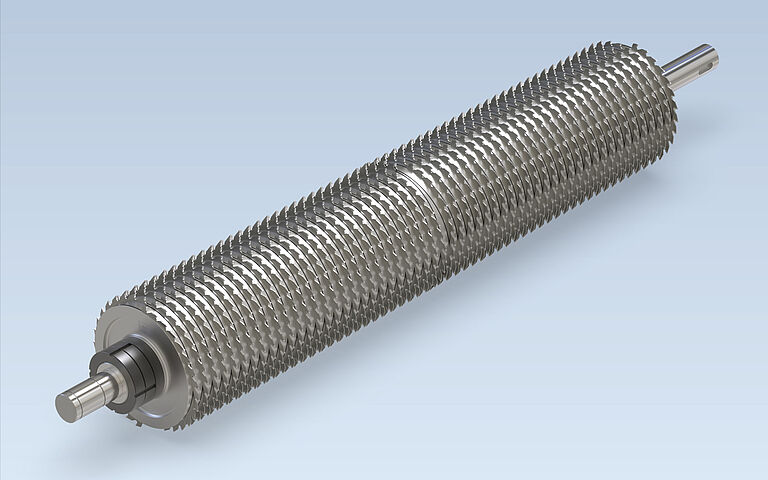

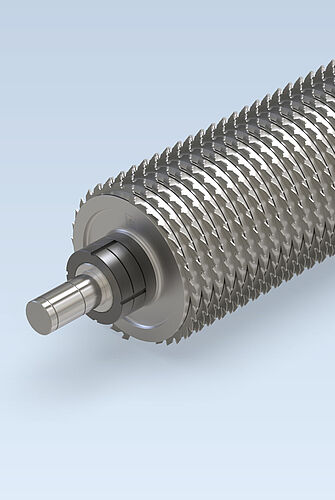

From the proven tool with tungsten carbide tipping, to the weight-optimized CentroFix interchangeable knife system or the highly productive system with circular sawblades, to the state-of-the-art HeliCut tool with interchangeable knives – Leitz offers the best possible solution for single or combination tools – individual or standard – depending on your requirements.

Grooving, shaping, shredding

From the semi-finished product to the individual product

Depending on the requirements and process design, individual tool solutions are needed for subsequent processing. With specific applications such as the insertion of grooves, the cutting of decorative molds or the re-processing of residual materials into the manufacturing process enables subsequent processing to be carried out quickly and cost-effectively.

Leitz, with its detailed process and material know-how, helps its customers find efficient and result-oriented tool solutions for every requirement.