Quality-Determining Interface

For machining wood, wood-derived materials, plastics and NF-metals

Quality is the word when it comes to selecting interfaces between machine and tool. Quality in regards to construction, tool steel and manufacturing quality, but also quality in protecting tools and machines and delivering the required machining results. High process reliability, perfect concentricity, high axial run-out accuracy, high balancing quality and maximum clamping force are just a few of the requirements that modern clamping devices and clamping systems must meet today. With the wide variety of clamping solutions offered today, the choice for customers can sometimes be overwhelming.

With its long experience in the machining of wood, wood-derived materials, plastics and NF-metals, Leitz offers a range of clamping devices that is perfectly matched to the type of machining, machine types and materials.

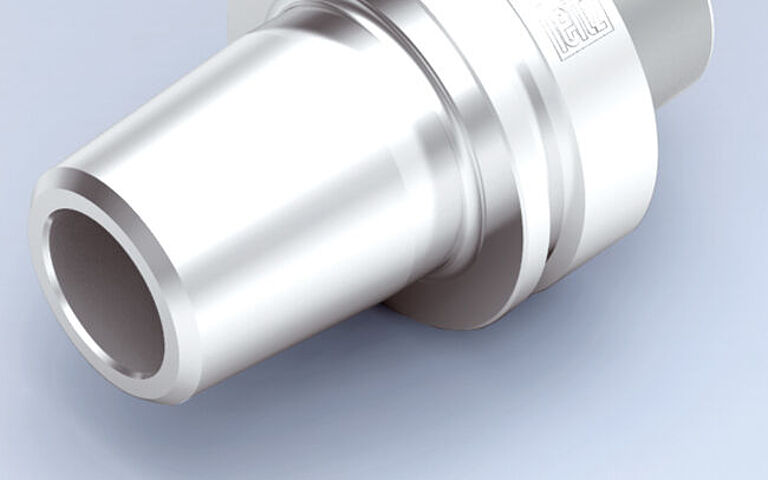

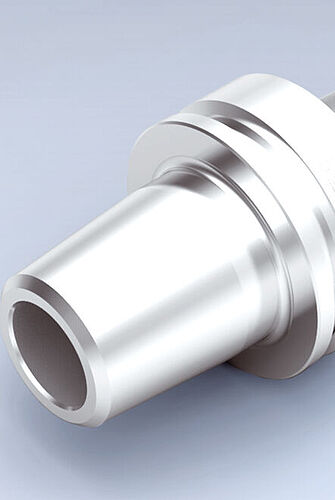

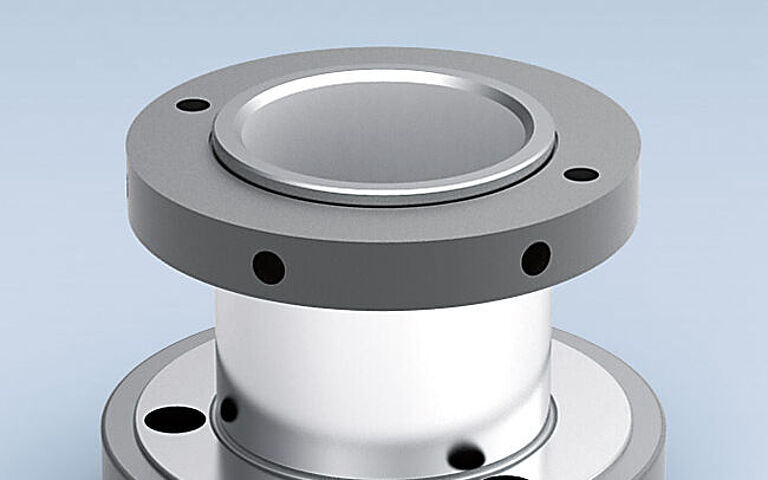

Clamping Systems For Stationary Machines

To be able to use tools on stationary machines and machining centers, chucks and clamping arbors with the appropriate spindle interface are required. These adaptations create the connection to the spindles that transmit the rotational movement to the system.

Leitz offers a range of shrink chucks, collet chucks, special drill chucks or clamping arbors for these machine and aggregate types, which perfectly transfers the performance of the machine to the tool and thus form a closed machining system.

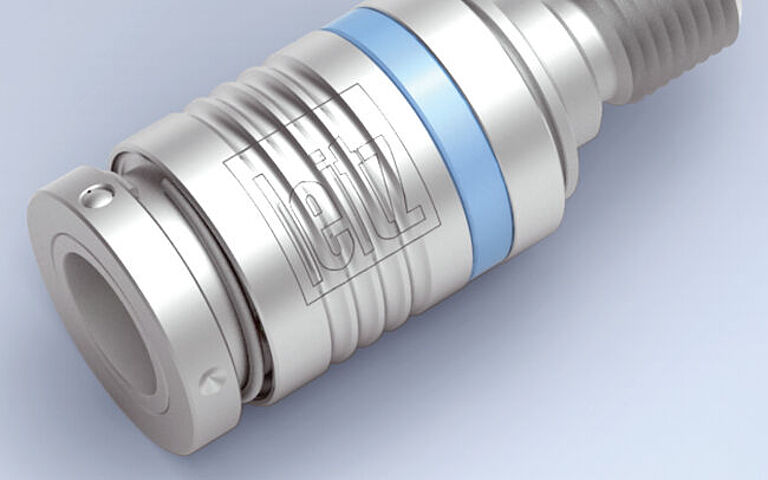

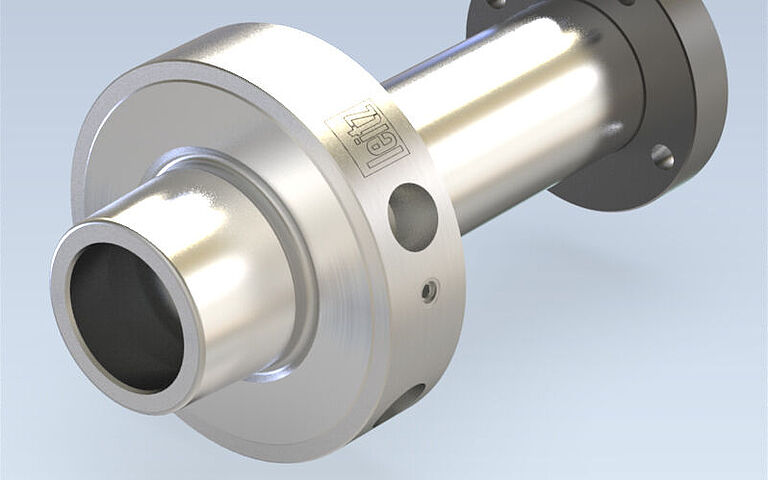

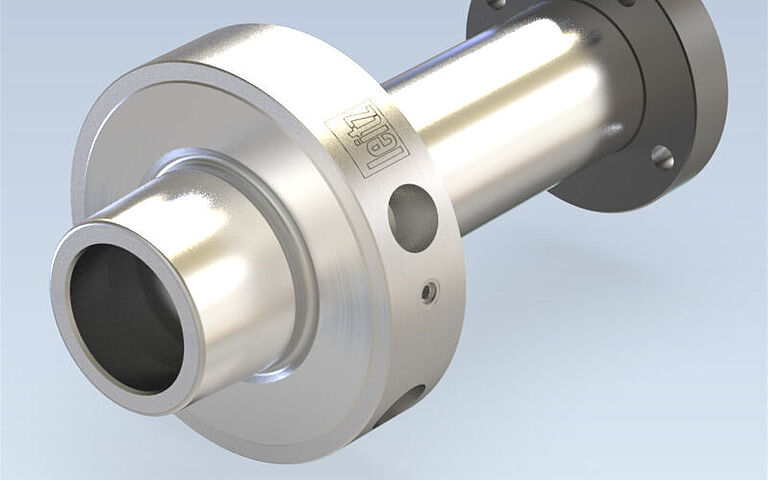

Clamping Systems For Through-Feed Machines

In order to be able to use tools on through-feed machines, clamping systems are required that adapt to the spindle shape or to a corresponding transmission shaft.

Leitz offers a comprehensive and well-selected product range of clamping sleeves, quick-clamping elements and hydraulic clamping systems, which guarantee the transmission of power to the tool.

Harlow,

Essex, CM19 5TN

United Kingdom