Versatile in use and particularly long-lasting

The best-known mineral material is Corian® and consists of one third acrylic glass (PMMA) and two thirds natural minerals with the main component of aluminium hydroxide. The fields of application are vast and range from decorative materials in thin sheet thickness, to medium-thick worktops, through to thicker sheets for covers, claddings and tables. Mineral working materials can be processed with conventional wood processing tools, and with its comprehensive standard range, Leitz offers ideal tool solutions for the most varied types of machining.

The solutions from Leitz

Processing in finish-cut quality

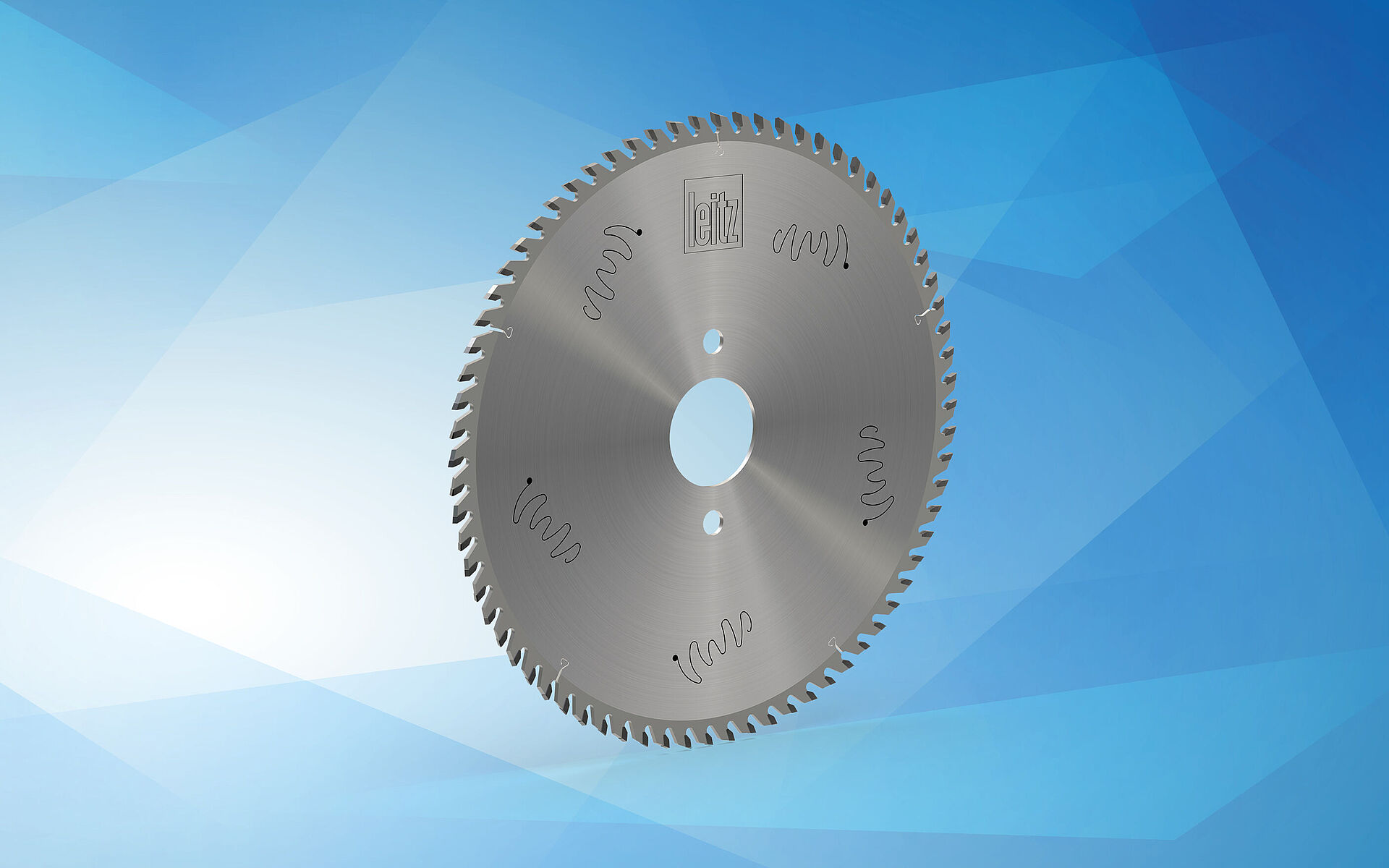

BrillianceCut HW circular sawblade: When it comes to perfect cutting areas and edges

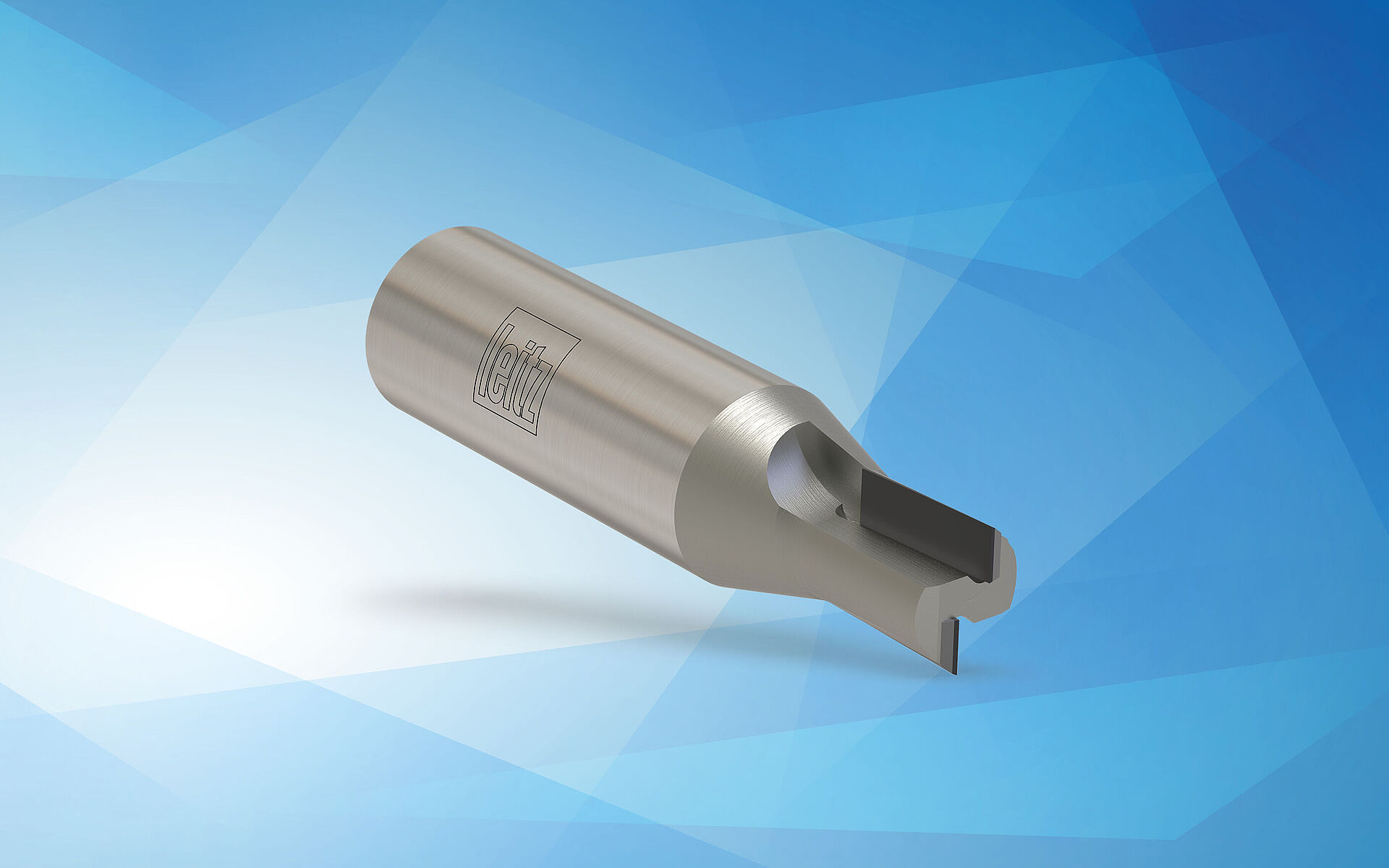

Router cutter Diamaster PLUS Z 2 with negative shear angle: The perfect tool for grooving with a tear and chip free machined edge

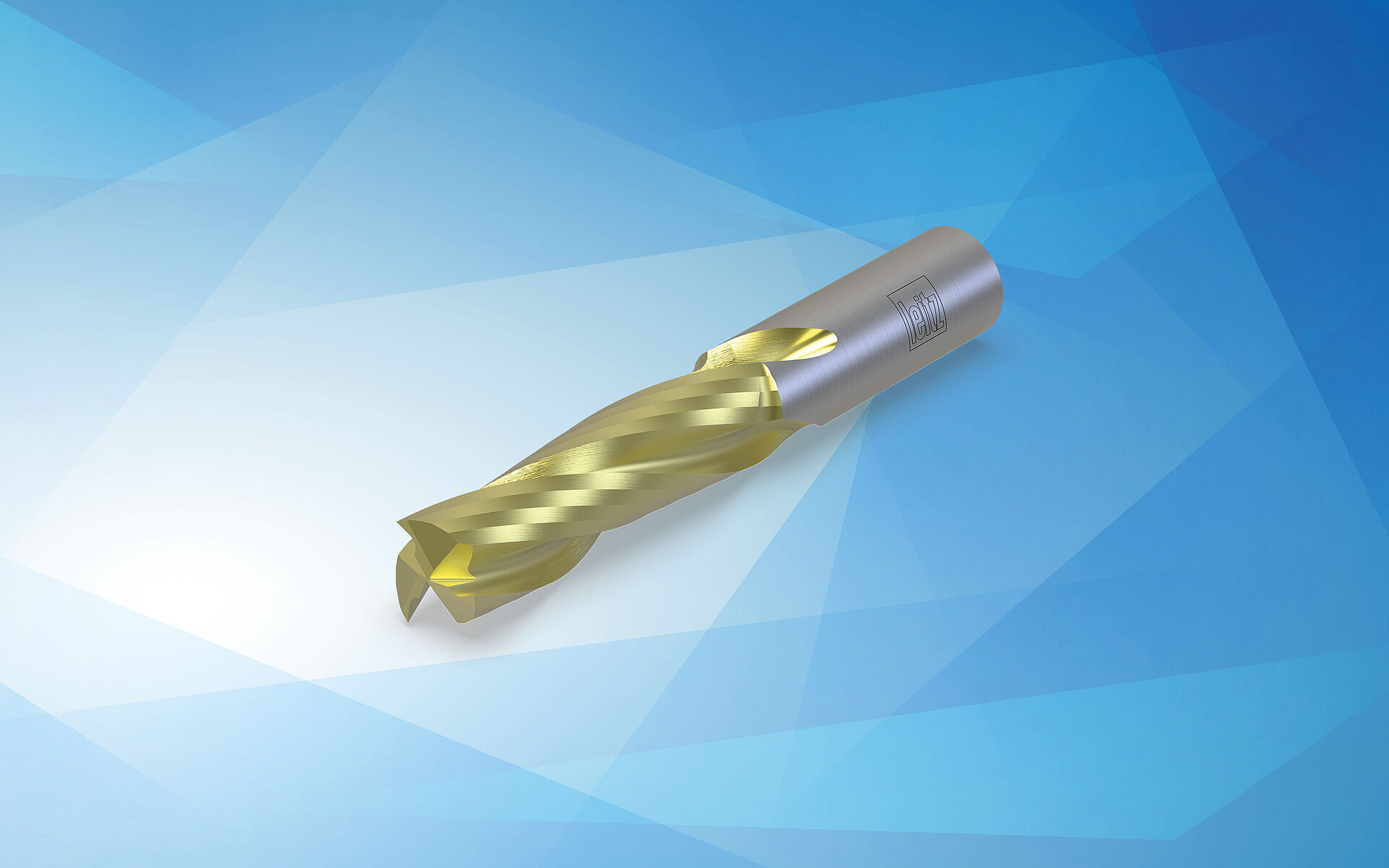

VHM spiral-finishing router Marathon: The tool for sizing, grooving and finish cutting with high demand on the cutting quality

Face milling cutter with stop ring: Router cutter for flush milling of bonded mineral material components

BrillianceCut HW circular sawblade

Quality & Efficiency

BrillianceCut HW circular sawblade

Quality & Efficiency

When it comes to perfect cutting areas and edges.

- Finish cut quality

- Reworking not required

- Long tool life

- Less noise

- Innovative tooth geometry

- Filled in laser ornaments

- Regrindable up to 20 times

- Diameter 303, 350, 380, 400 and 450 mm

- For all conventional panel sizing and sizing sawblades

- Available from stock

Router cutter Diamaster PLUS Z 2 with negative shear angle

Productivity & Efficiency

Router cutter Diamaster PLUS Z 2 with negative shear angle

Productivity & Efficiency

The perfect tool for grooving with a tear and chip free machined edge.

- High cutting performance

- Long tool life

- 5-8 times resharpenable

- Negative shear angles for tear-free edges when grooving

- Excellent stability thus particularly suitable for cutting HPL

- The cutting pressure supports workpiece clamping for small machined parts in the nesting process

- Coordinated tool programme with diameter 14 and 16 mm

- For all conventional machines

- Available from stock

- Diamond-tipped

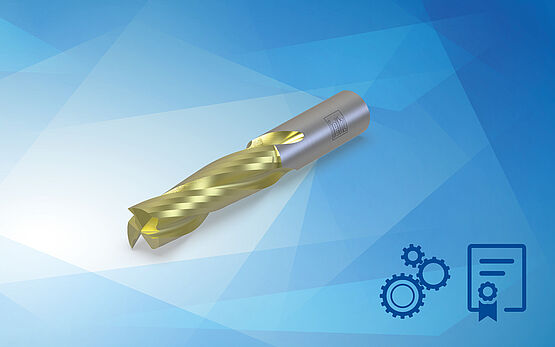

VHM spiral-finishing router Marathon

Productivity & Quality

VHM spiral-finishing router Marathon

Productivity & Quality

The tool for sizing, grooving and finish cutting with high demand on the cutting quality.

- High cutting performance

- Finishing quality

- High feed rates

- Long life time

- Coordinated tool programme in the diameter range 12-20 mm

- Suitable for all conventional machines

- Available from stock

- Marathon coating

Face milling cutter with stop ring

Quality & Efficiency

Face milling cutter with stop ring

Quality & Efficiency

Router cutter for flush milling of bonded mineral material components.

- Perfect cutting quality

- Optimum edge formation

- Long life time

- Coordinated tool programme in the diameter range 12-20 mm

- For manual feed

- Available from stock

- Marathon coating