Special properties, special solutions

Only optimally coordinated processes and tools ensure success

A closer look at various types of plastics shows an almost unbelievable abundance of material, processing and application possibilities. However, a key distinction is made between the material groups of thermoplastics, duroplastics and elastomers. Each of these material groups has its own special properties and each material has different features which have to be taken into account during machining.

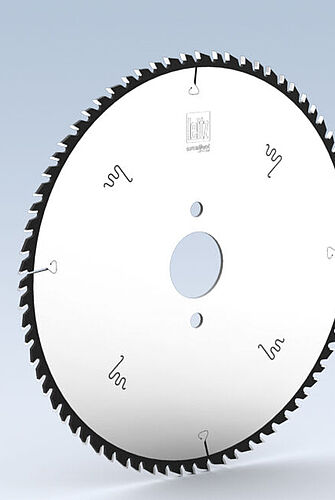

Leitz knows that only tool solutions adapted to the material and the respective process guarantee optimum success in terms of quality, efficiency and safety. Leitz proves this with the solutions from its standard tool range but also within individual tool system solutions that make for very satisfied Leitz customers.

Thermoplastics

Special working material

In the machining of thermoplastics, the choice of process parameters is of great importance, besides the special tooth geometries and gullet areas. Transparent plastics, such as acrylic glass, also play a special role. It is here above all that all the cutting edges and cutting surfaces that must be smooth and free of marks so that the overall appearance of the workpiece is not damaged. This is made possible by special machining tools that are equipped with corresponding geometries and cutting materials.

Leitz offers a variety of tried and tested tool solutions in the field of panel cutting, shape and contour milling. In addition, Leitz has solutions for boring blind and through-holes for materials such as acrylic glass (PMMA), polycarbonate (PC), polyvinyl chloride (PVC) or polystyrene (PS).

Duroplastics

A material with specific properties

Duroplastics are usually brittle and hard. The temperature is not the most important factor during machining sothe cutting speeds are higher than for thermoplastics. Because of the brittle-hard material properties and the abrasive effect of the embedded fibres, the tools differ in geometry and cutting material from those used for machining thermoplastics. Diamond is the preferred cutting material.

Typical examples of duroplastic materials include compact laminates, high-pressure laminates (HPL laminates) made of melamine or phenolic resin-impregnated paper or printed circuit boards (PCBs) made of hard paper.

Mineral-bound materials

Versatile in use and particularly long-lasting

The best-known mineral material is Corian® and consists of one third acrylic glass (PMMA) and two thirds natural minerals with the main component of aluminium hydroxide. The fields of application are vast and range from decorative materials in thin sheet thickness, to medium-thick worktops, through to thicker sheets for covers, claddings and tables.

Mineral working materials can be processed with conventional wood processing tools, and with its comprehensive standard range, Leitz offers ideal tool solutions for the most varied types of machining.

Downloads

73447 Oberkochen

Germany