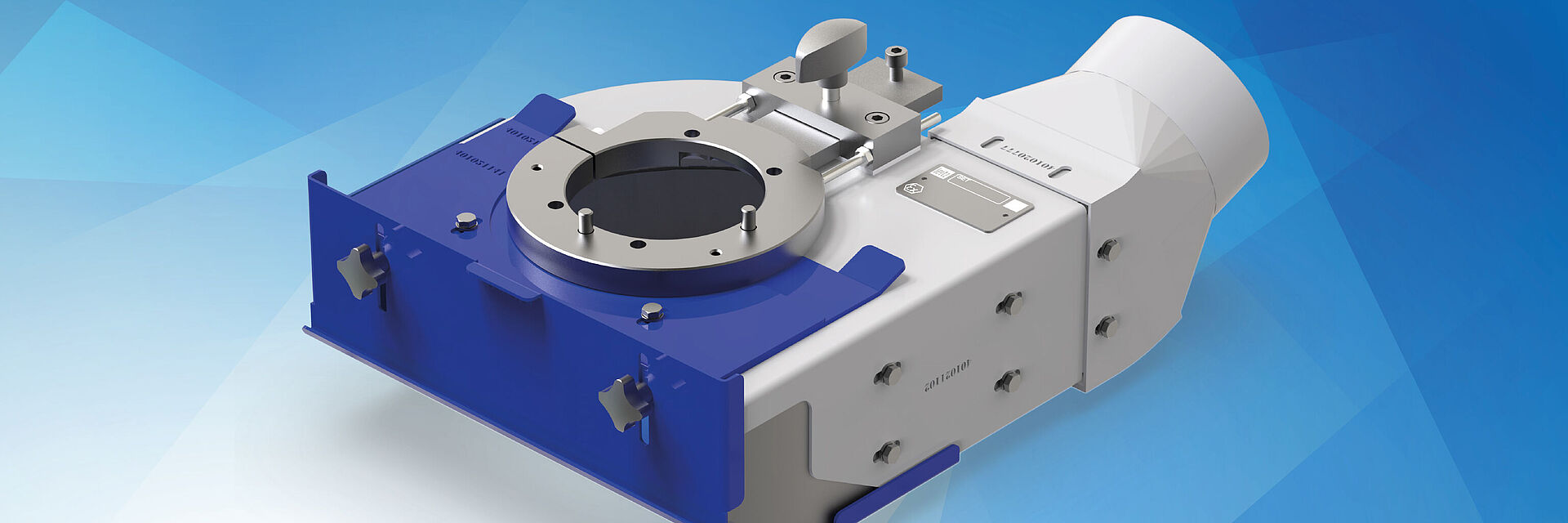

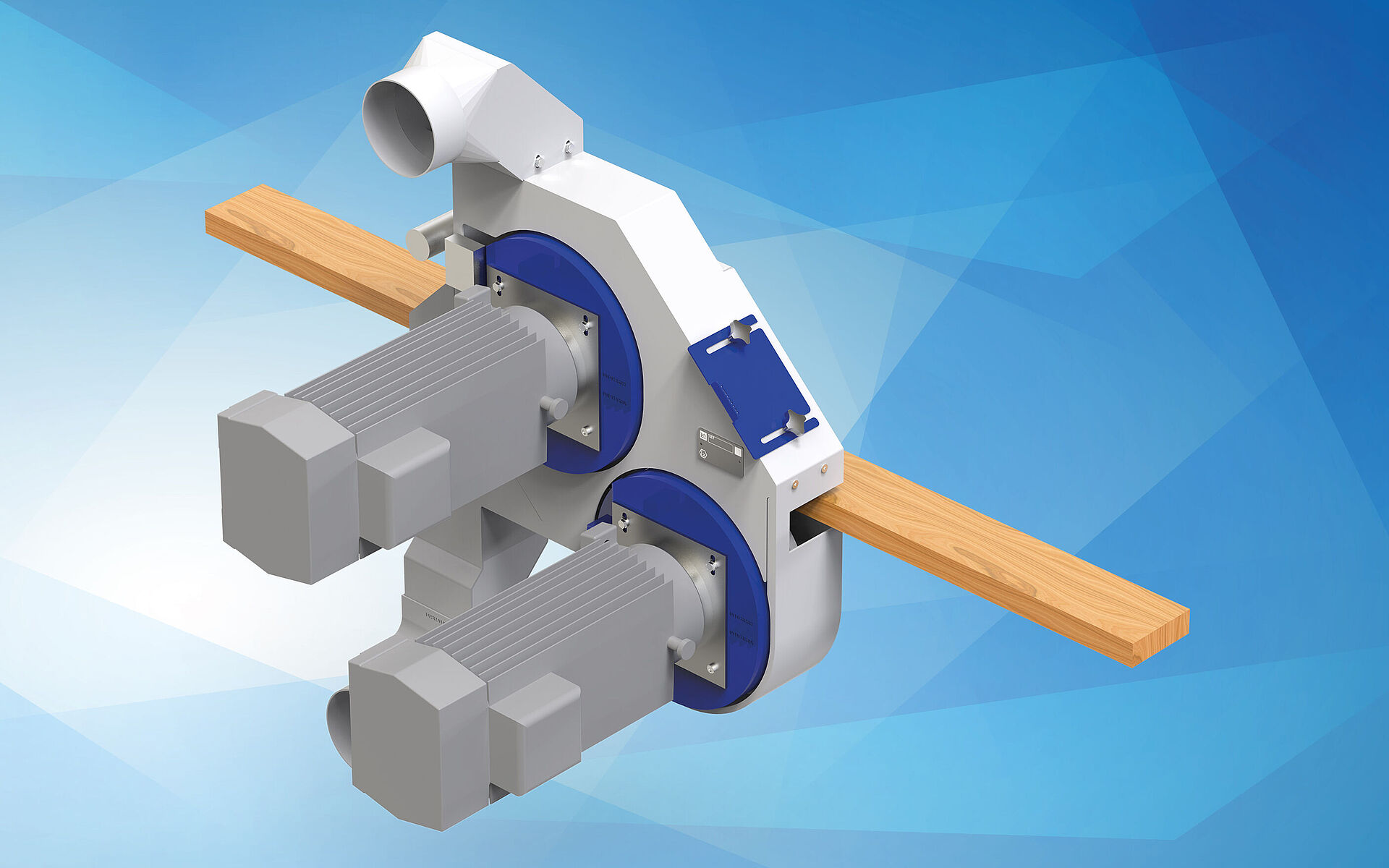

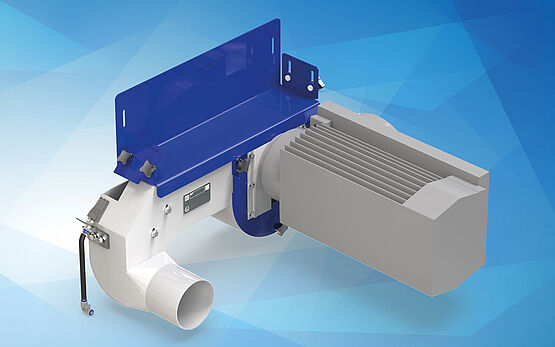

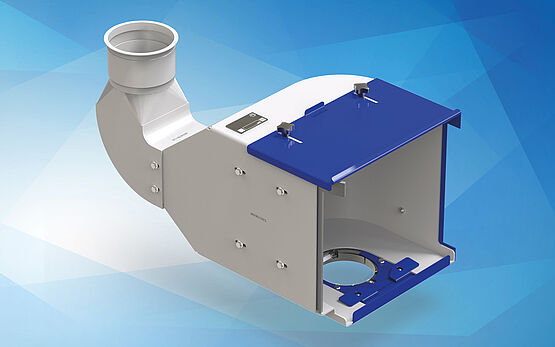

DFC®ダストフローカバーフード

きれいな機械、完璧な加工材

ダストフローカバーフードは機械加工の生産工程全体に多大な影響を与えます。ツールと囚人フードが完全にマッチしていることが重要です。ライツのDFC®ダストフローカバーフードは個別に設計され、それぞれの要件に合わせて正確にカスタマイズされます。成型プロファイルのバリエーションやさまざまな厚みの材など、すべての加工オプションを考慮します。ご要望に応じて、セラミックコーティングにより摩耗を最小限に抑えることも可能です。

集塵効率を最適化: 二重切削がなく、集塵効率アップによりツールの長寿命化をサポート。

火災防止: ダストフローカバーフードの最適な調整により粉塵の発生を抑え、火災のリスクを低減。

時間とコストを削減: DFC®技術でツールの交換やマシンの非稼働時間を大幅に短縮

持続可能性: DFC®ダストフローカバーフードは、エネルギー消費量を削減しながらも最大限の性能を発揮します。

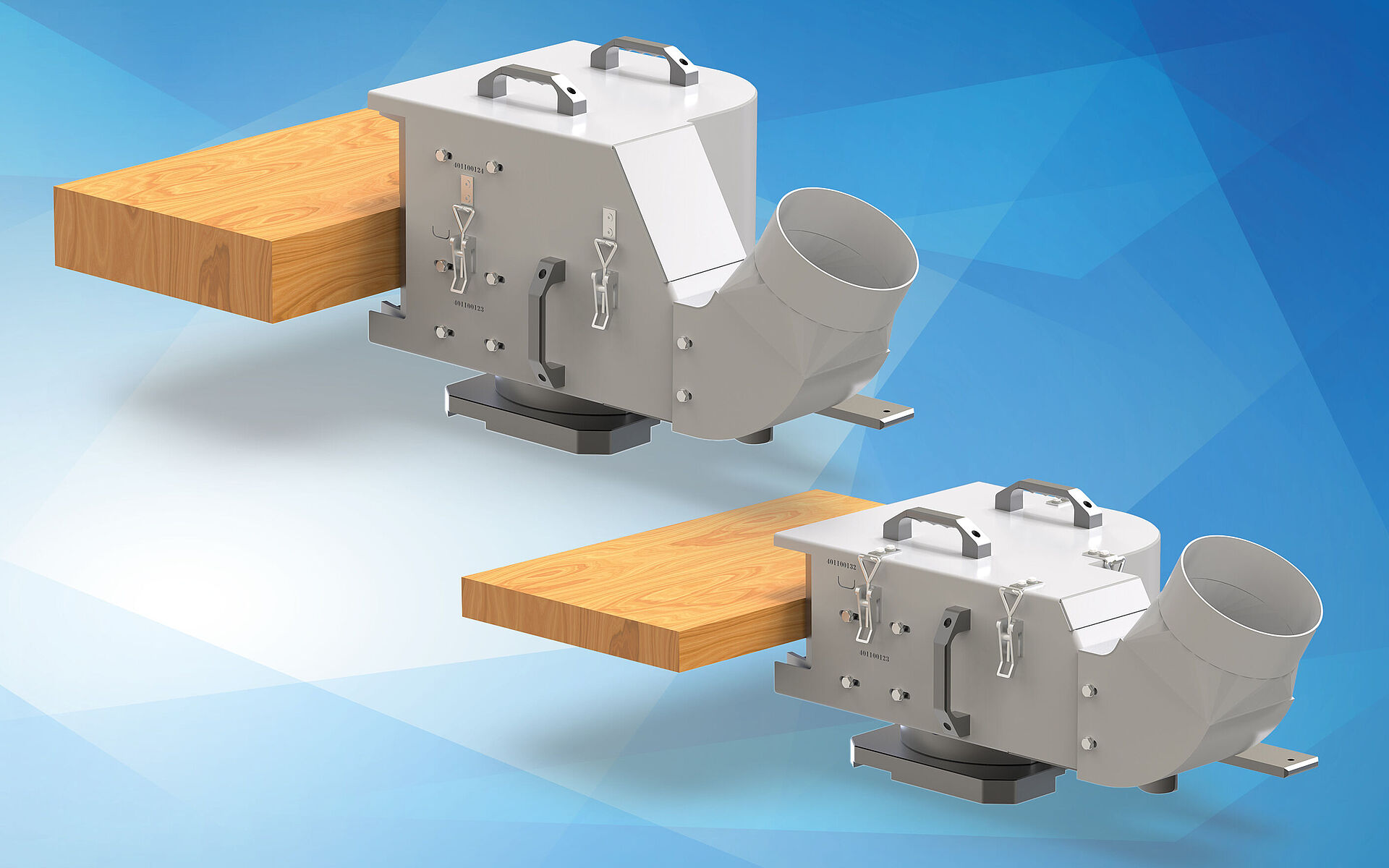

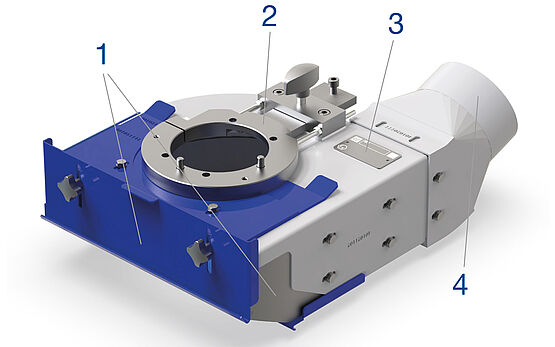

1) 交換可能なウェアプレートによる耐久性のある集塵フード

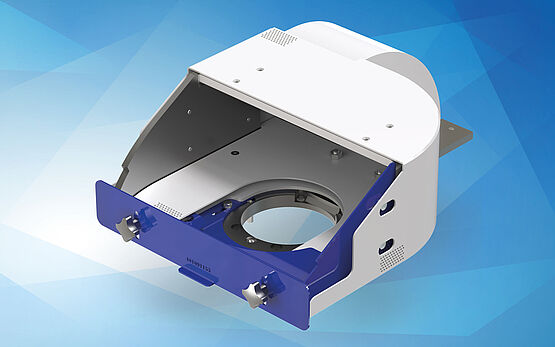

2) 簡単な組み立てによる素早いツール交換

3) すべての部品にステッカーとラベルを貼付することで、スペアパーツの管理が簡単

4) カスタマイズされた寸法による効率的な集塵性能

Focus on customer needs

Before a new extraction hood is designed, the conditions on site are measured by a Leitz technician and all needs and requirements are precisely determined. All this information is then taken into account in the design. In this way, each extraction hood is customised to the respective requirements, resulting in a clean machine and perfect workpieces.

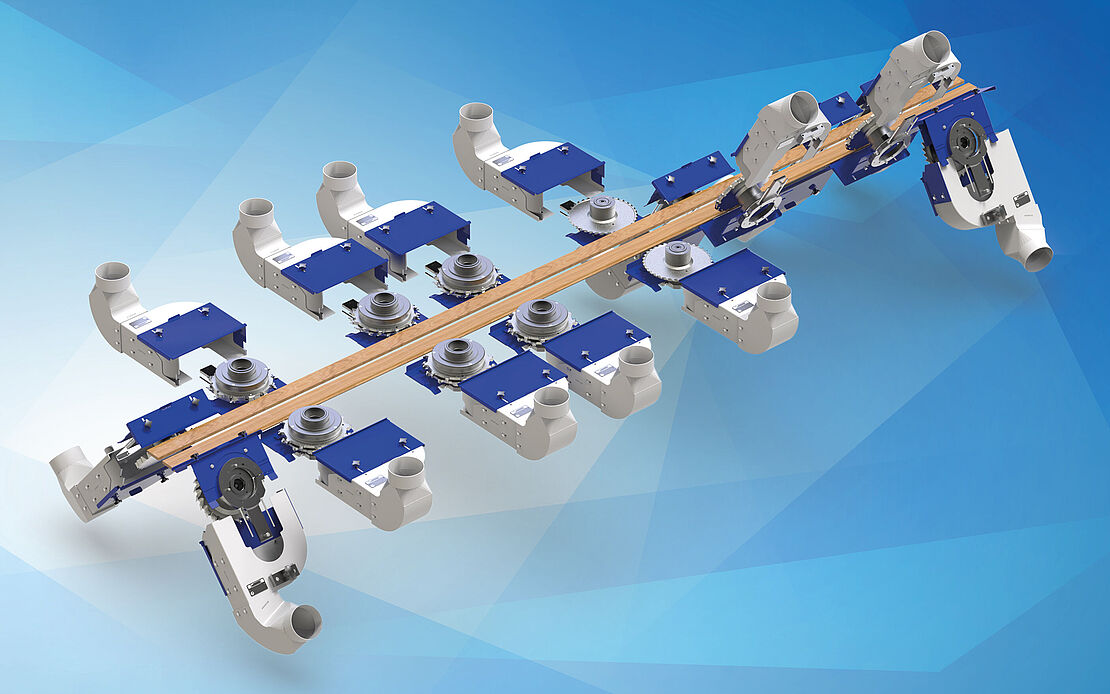

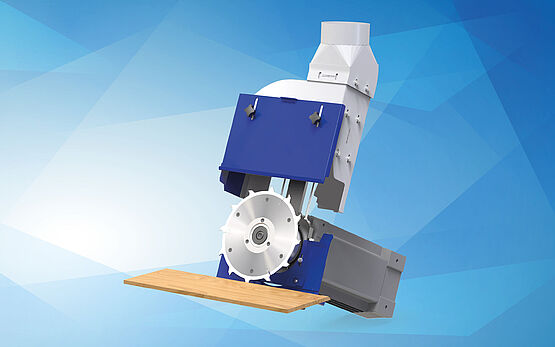

Floor production

Floor production

The roots of the Leitz DFC®-Extraction hood are in the flooring industry. A modular system customised to the industry with individual adaptation to the machine environment and profiles leads to fast and efficient project handling.

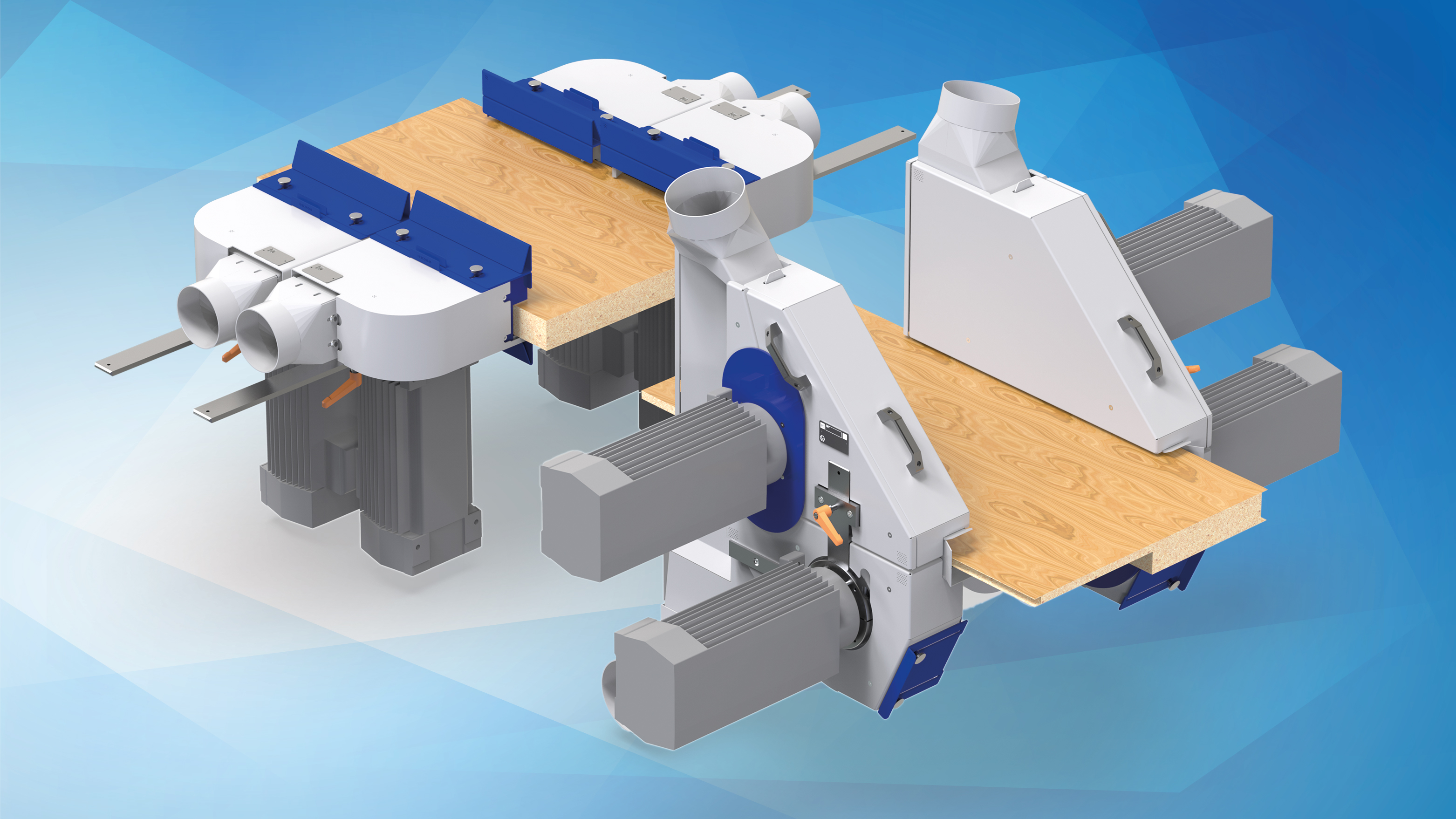

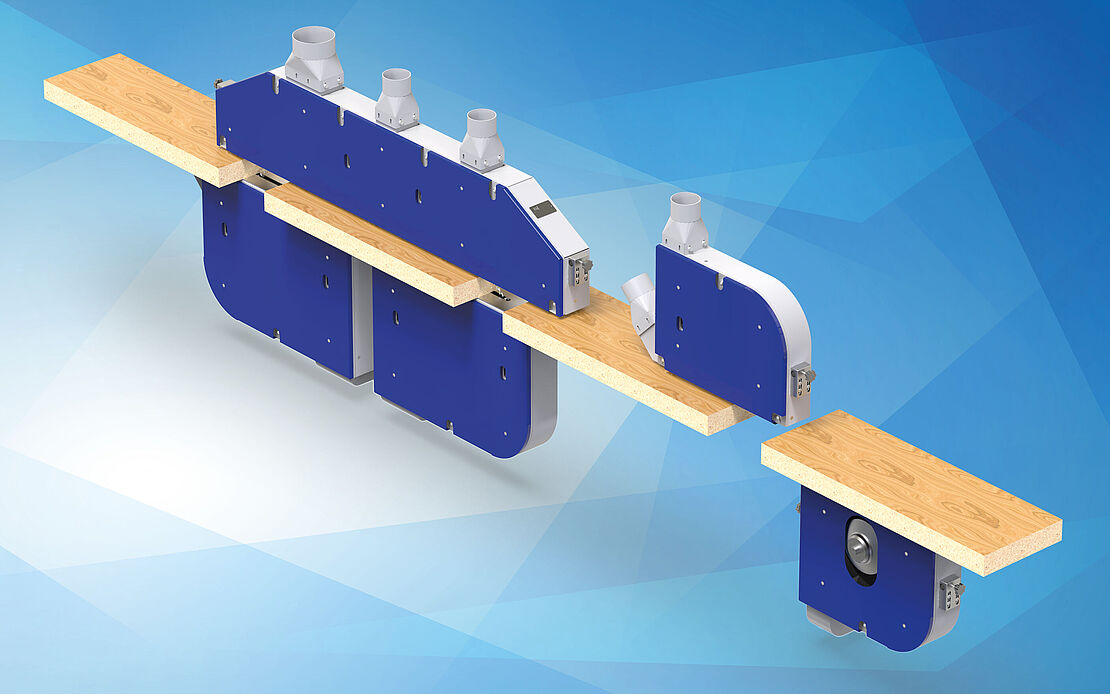

Furniture industry

Furniture industry

Whether for large machining operations or fine profiling and jointing work, the panels must be free of dust and chips in furniture production. Loose edges and pressed-in chips lead to rejects or reworking. These risks can be minimised with perfectly adapted extraction hoods.

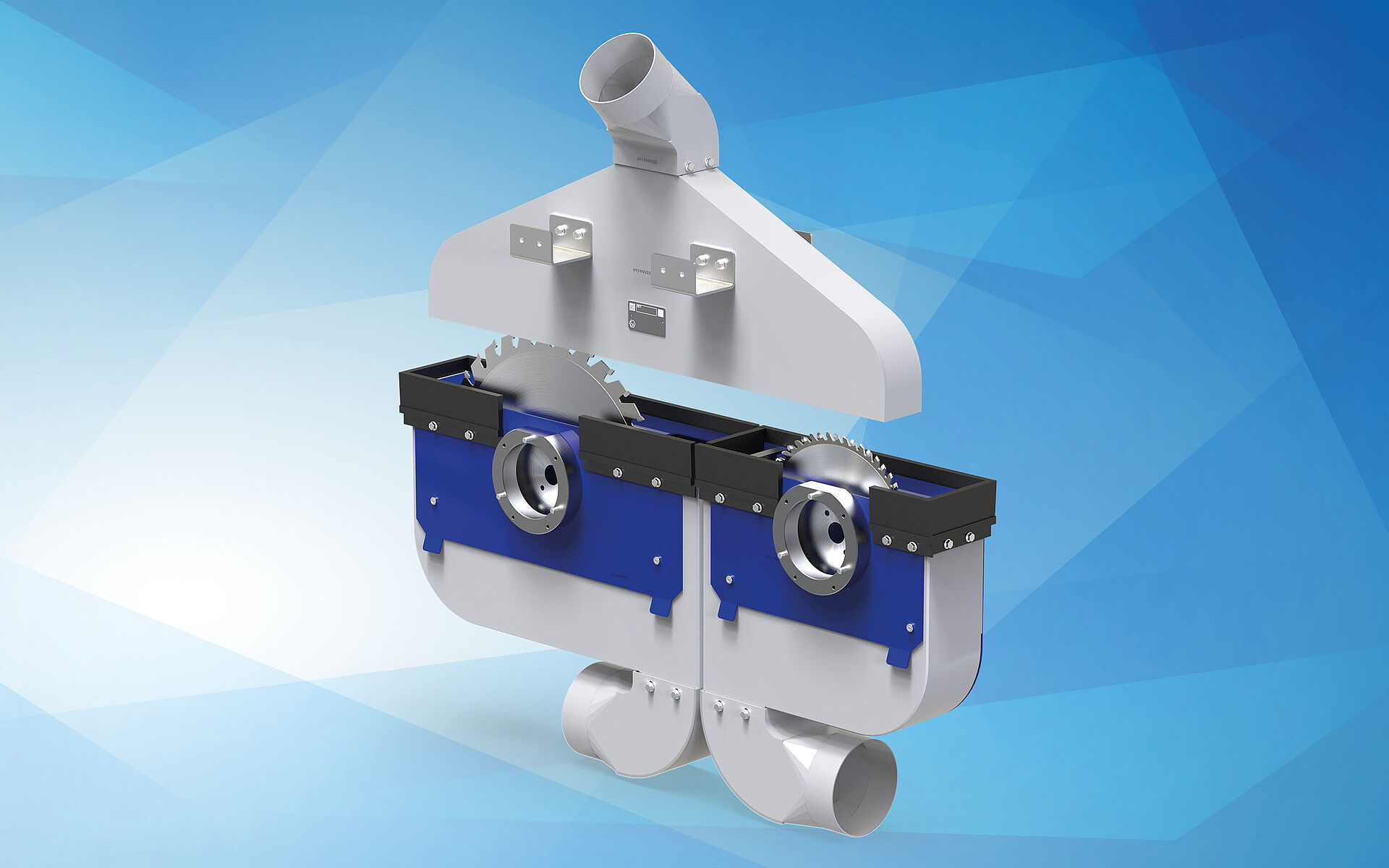

Leitz has also repeatedly improved the plate-splitting process with extraction hoods. In addition to the removal of chips, the issue of noise plays a central role here. The LowNoise version delivers significant improvements here!

Advanced Materials

Leitz extraction hoods are as diverse as the materials on the market. Whether abrasive fibre cement for facades or soft foam for insulation, each material has different requirements. By using a special ceramic coating for abrasive materials, the lifetime of the extraction hoods can be extended by a factor of more than 10.

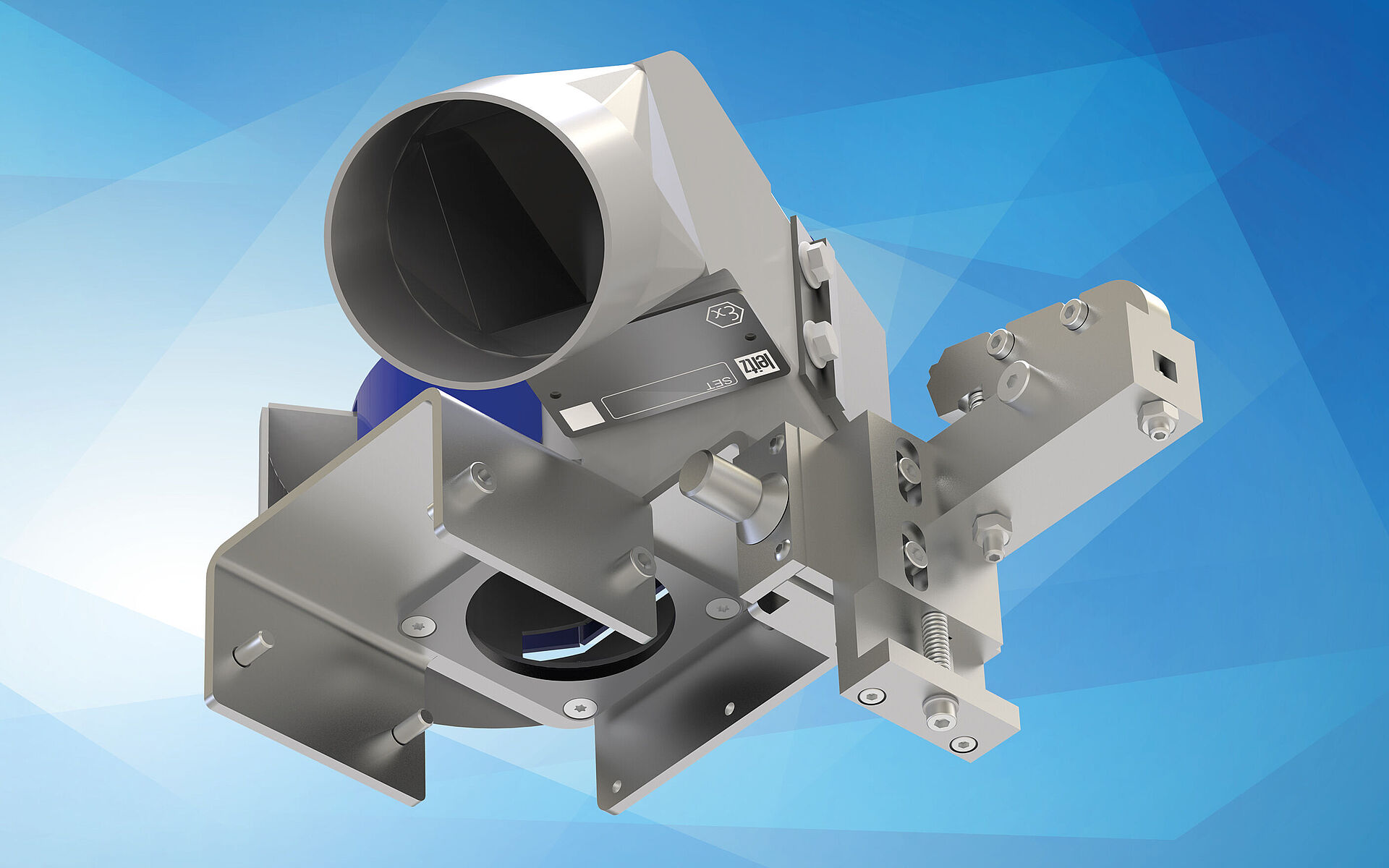

Jet nozzle

Jet nozzle

For with feed grooving to clean the groove and for special applications, a jet nozzle can be used as an air curtain instead of classic brushes.

LowNoise design

LowNoise design

A special external construction reduces the sound level by up to 5 dB(A).

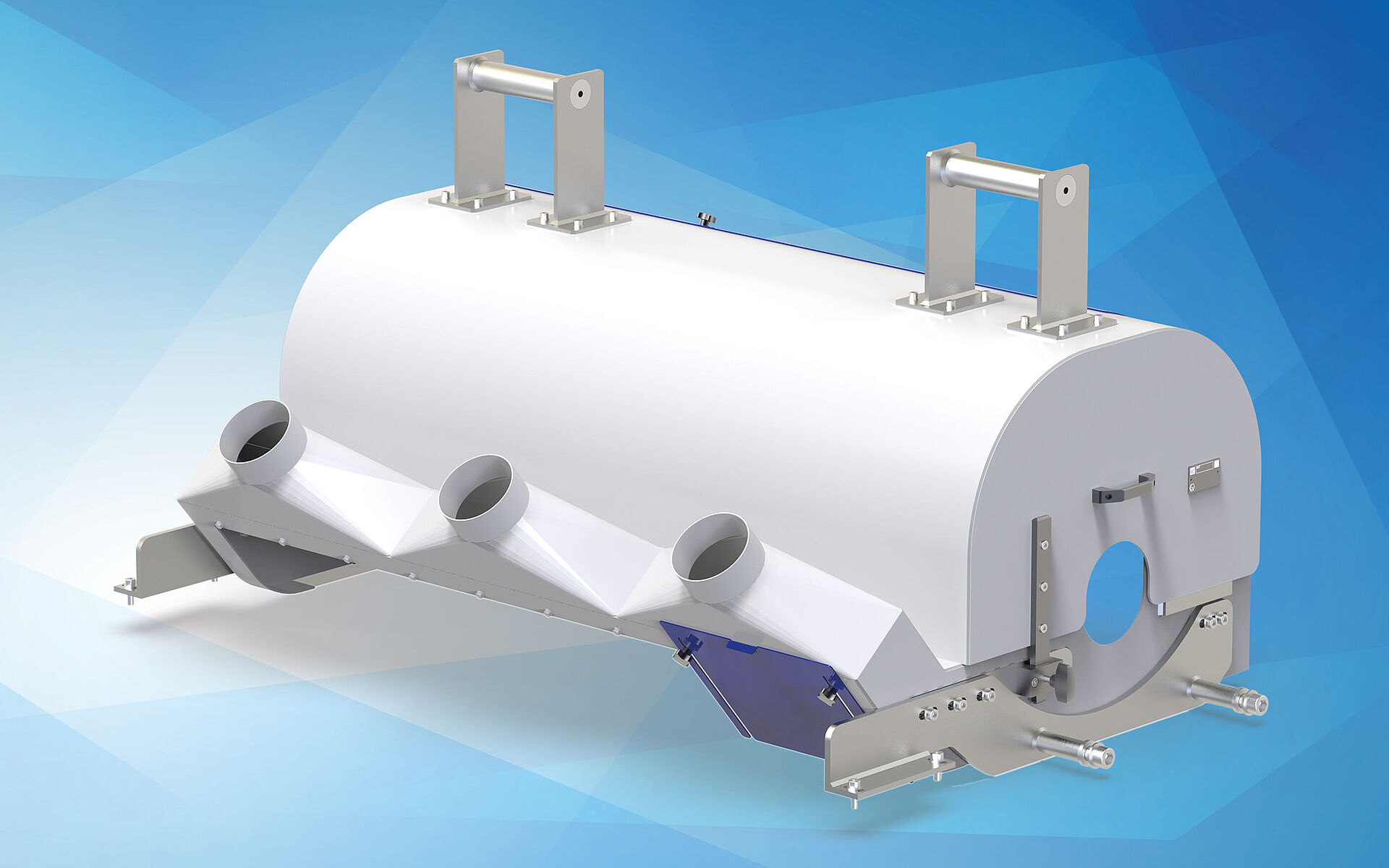

Lightweight construction

Lightweight construction

Lightweight extraction hoods can be used for large processing thicknesses and non-abrasive materials. An aluminium body and weight-reduced steel parts ensure a weight saving of around 30 %. The focus here is on ergonomics.

Special versions

Every project is individual. Thanks to Leitz‘s many years of experience in the construction of special hoods of all kinds, there is a suitable extraction hood for every requirement.