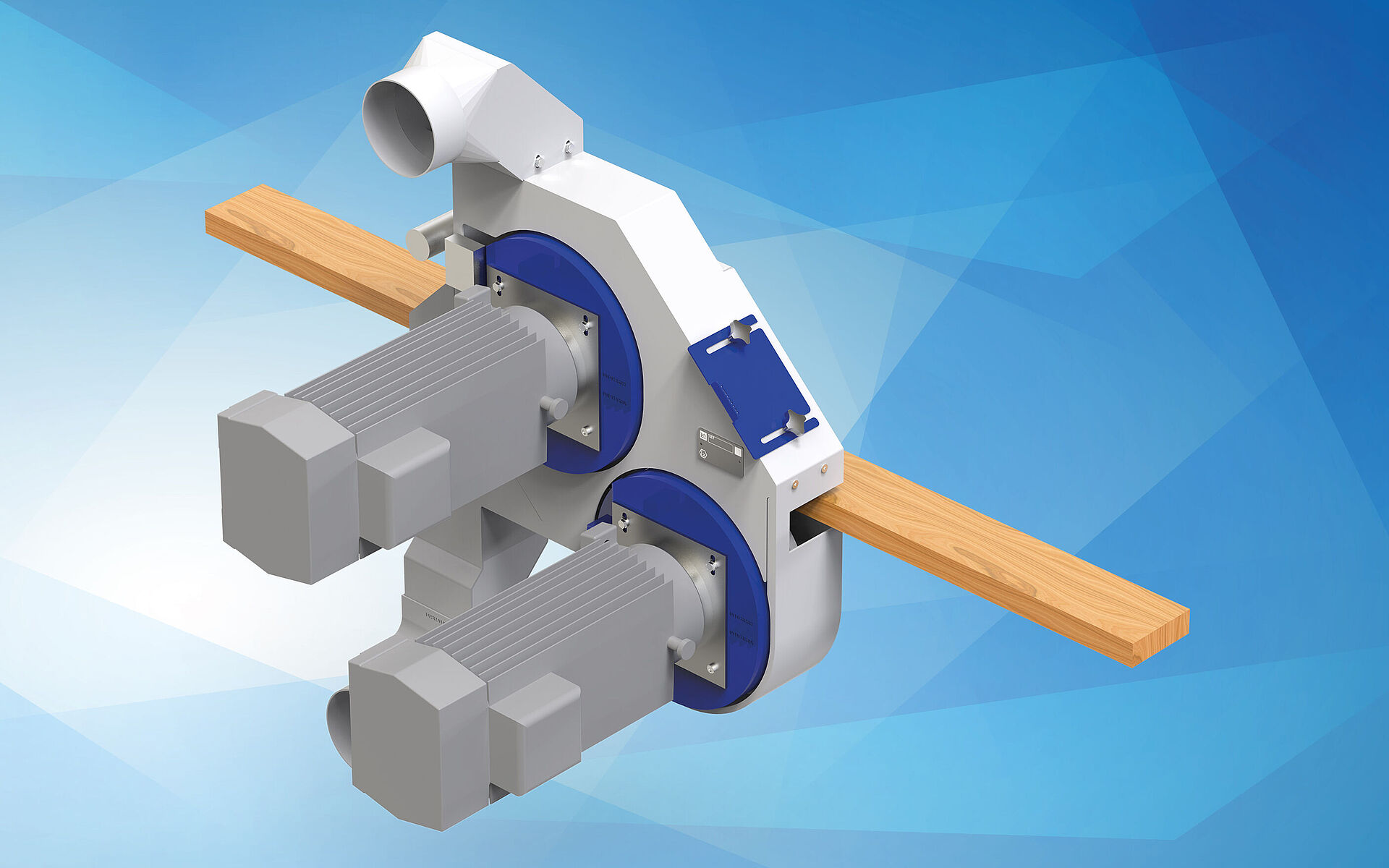

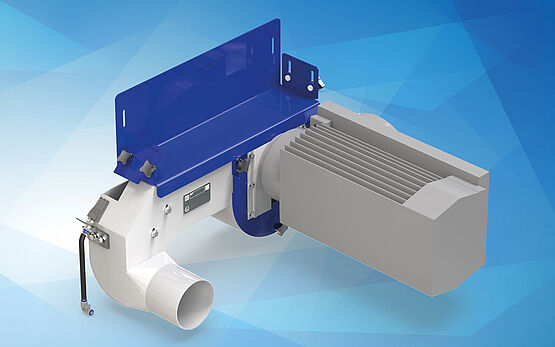

Capotas de exaustão Leitz DFC®

Máquinas limpas, peças perfeitas

As capotas de exaustão têm uma influência enorme em todo o processo de fabricação durante a usinagem. É importante que a ferramenta e a capota de exaustão sejam perfeitamente compatíveis. As capotas de exaustão DFC® Leitz, são projetados individualmente e ajustados com precisão às respectivas necessidades. Todas as opções de processamento, como variantes de perfil ou diferentes espessuras de material, são levadas em consideração. Se desejado, a blindagem cerâmica direcionada pode reduzir o desgaste ao mínimo absoluto.

Fluxo de cavacos otimizado: sem contato duplo no corte, melhor coleta de cavacos e maior vida útil da ferramenta.

Prevenção de incêndio: menor acúmulo de poeira e, portanto, menor risco de incêndio graças ao ajuste otimizado das capotas.

Economia de tempo e custos: trocas de ferramentas mais rápidas e tempos de inatividade da máquina significativamente reduzidos graças ao design ergonômico.

Sustentabilidade: as Capotas de Exaustão DFC® oferecem desempenho máximo com consumo reduzido de energia.

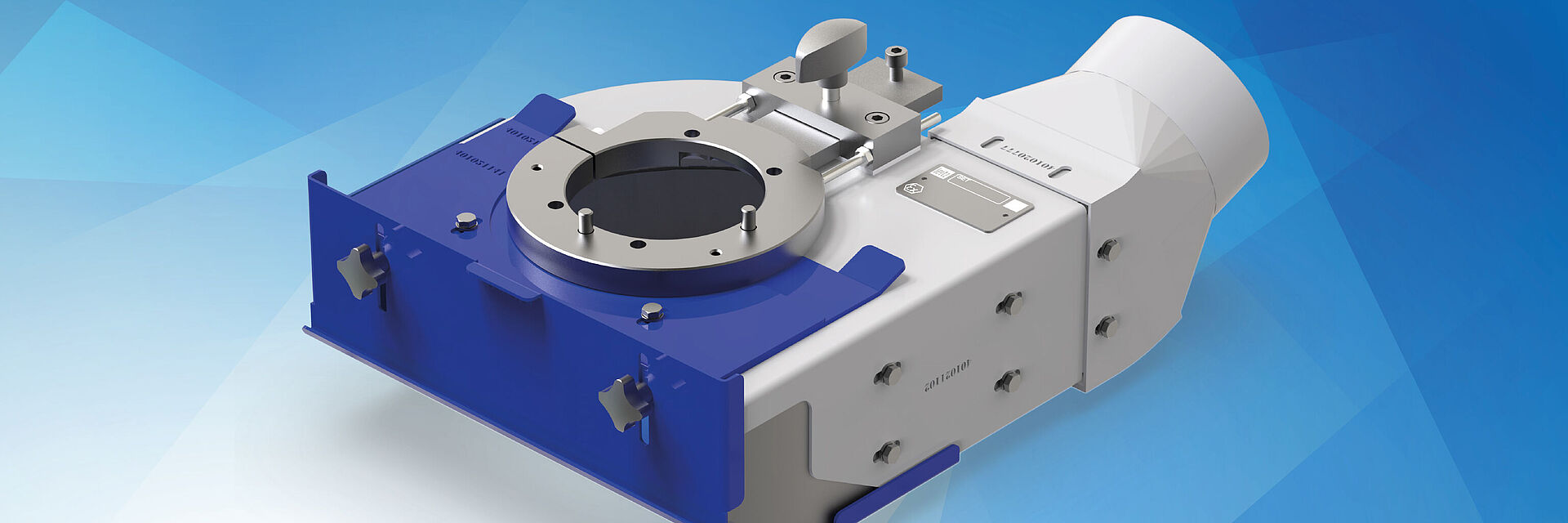

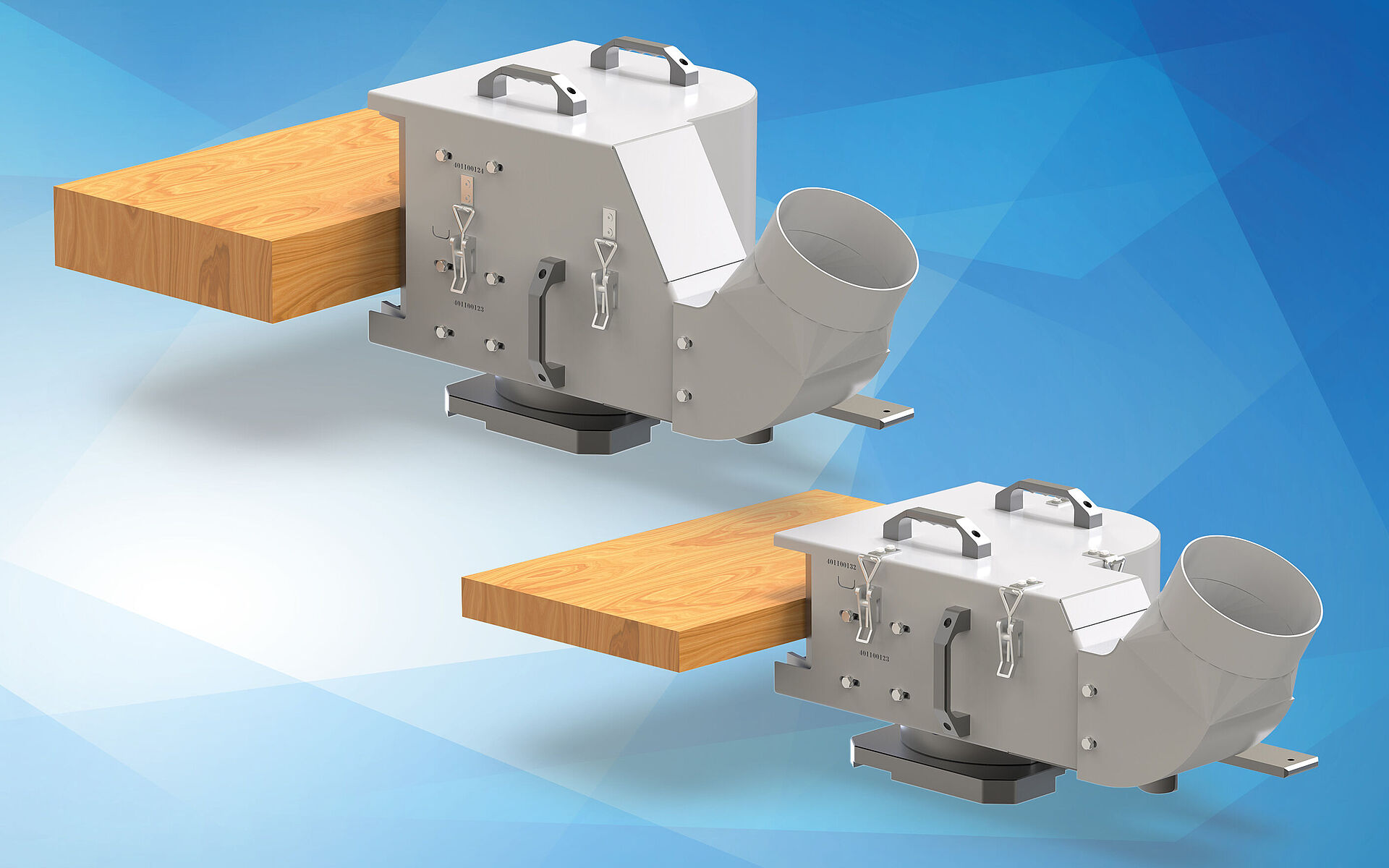

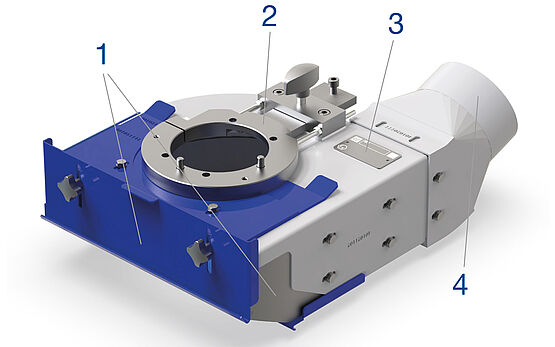

1) Capostas de exaustão duráveis graças às placas de desgaste substituíveis

2) Troca rápida de ferramentas graças à montagem simples

3) Gerenciamento simples de peças de reposição graças aos adesivos e etiquetagem de todos os componentes

4) Desempenho de extração eficiente graças aos diâmetros personalizados

Focus on customer needs

Before a new extraction hood is designed, the conditions on site are measured by a Leitz technician and all needs and requirements are precisely determined. All this information is then taken into account in the design. In this way, each extraction hood is customised to the respective requirements, resulting in a clean machine and perfect workpieces.

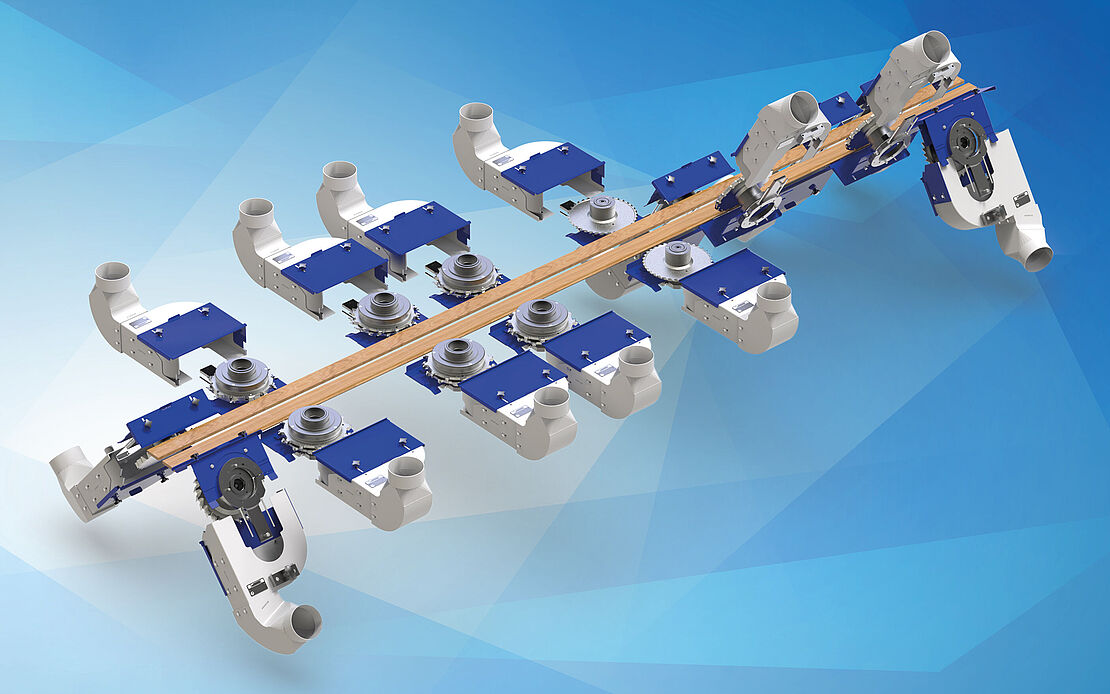

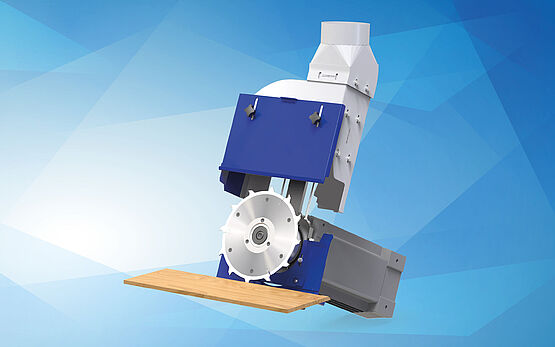

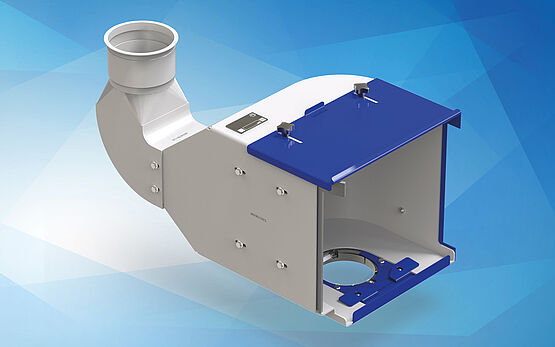

Floor production

Floor production

The roots of the Leitz DFC®-Extraction hood are in the flooring industry. A modular system customised to the industry with individual adaptation to the machine environment and profiles leads to fast and efficient project handling.

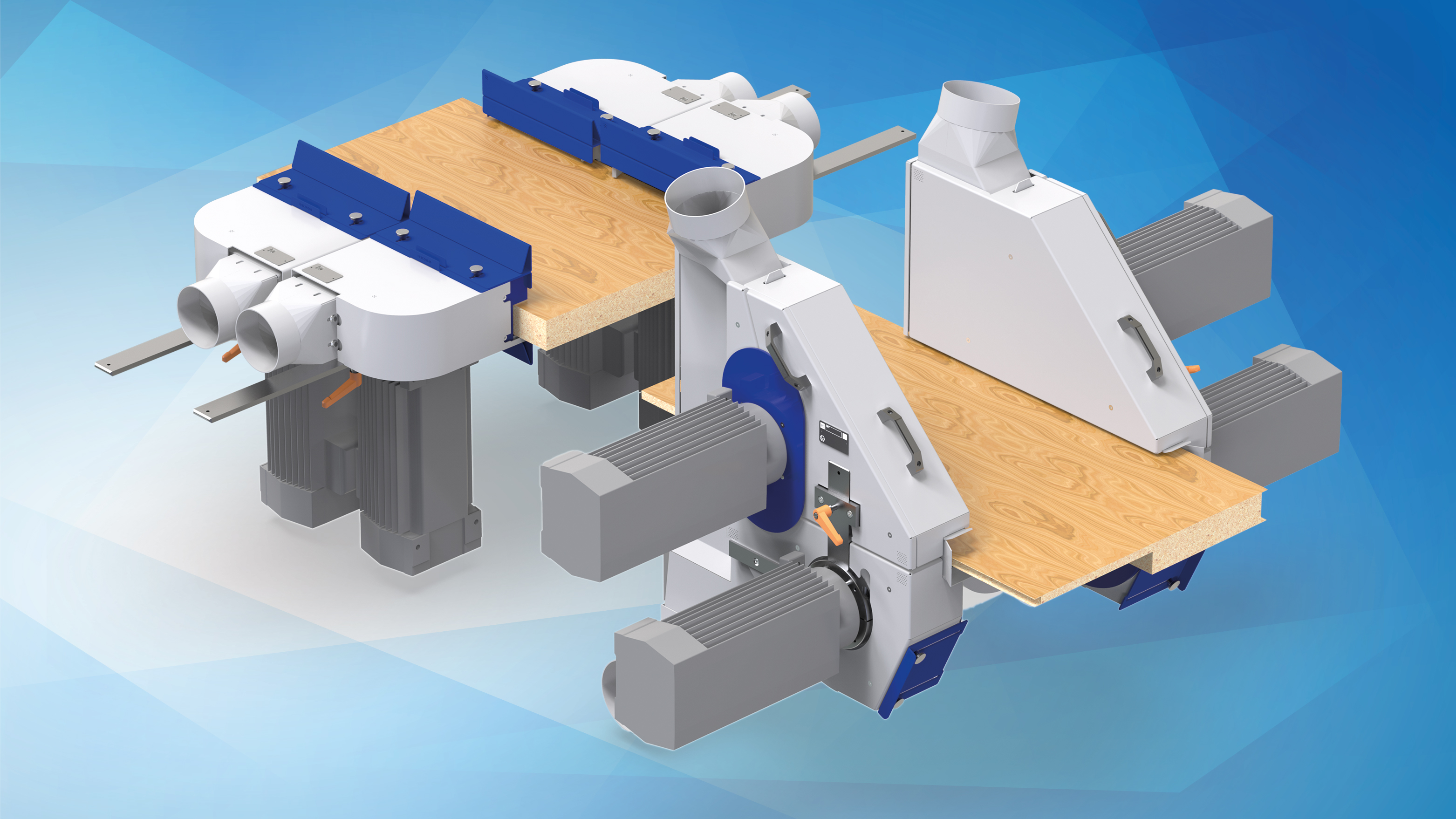

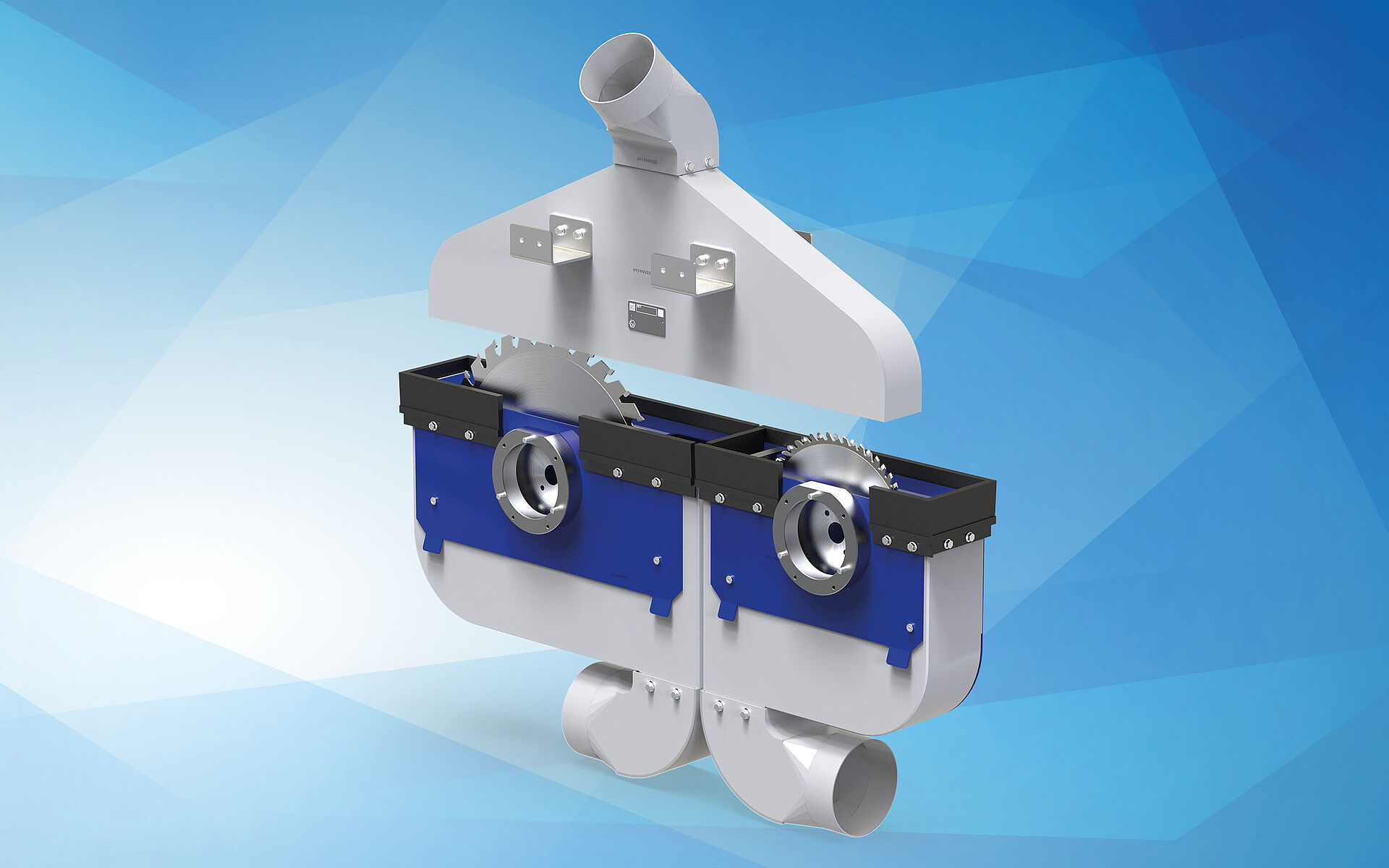

Furniture industry

Furniture industry

Whether for large machining operations or fine profiling and jointing work, the panels must be free of dust and chips in furniture production. Loose edges and pressed-in chips lead to rejects or reworking. These risks can be minimised with perfectly adapted extraction hoods.

Leitz has also repeatedly improved the plate-splitting process with extraction hoods. In addition to the removal of chips, the issue of noise plays a central role here. The LowNoise version delivers significant improvements here!

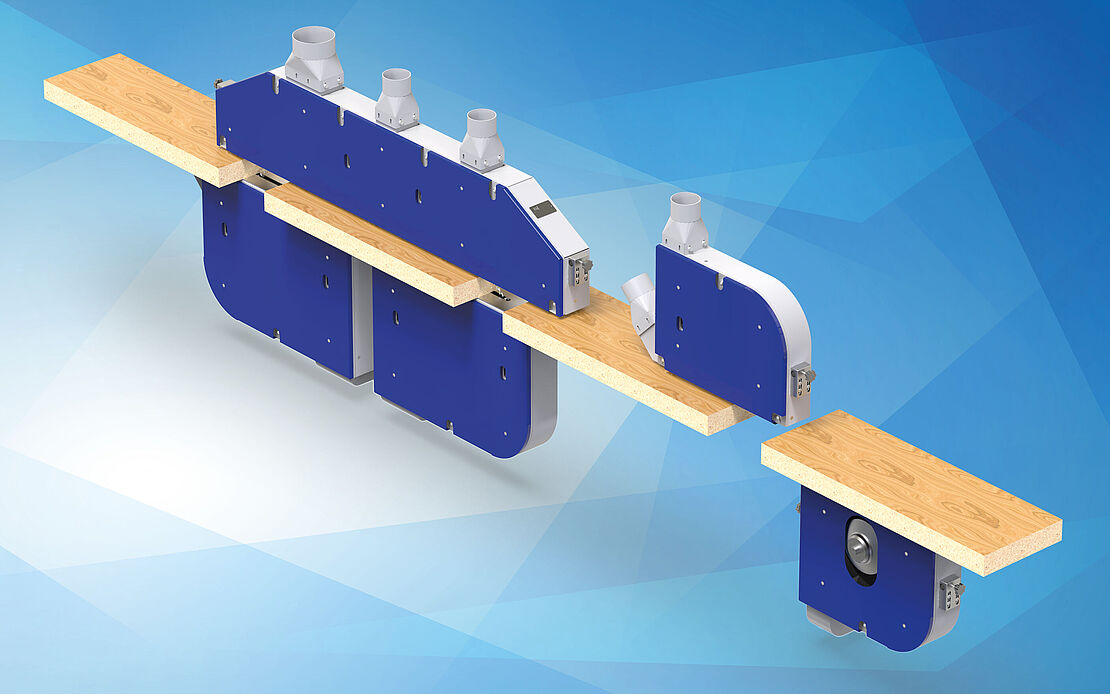

Advanced Materials

Leitz extraction hoods are as diverse as the materials on the market. Whether abrasive fibre cement for facades or soft foam for insulation, each material has different requirements. By using a special ceramic coating for abrasive materials, the lifetime of the extraction hoods can be extended by a factor of more than 10.

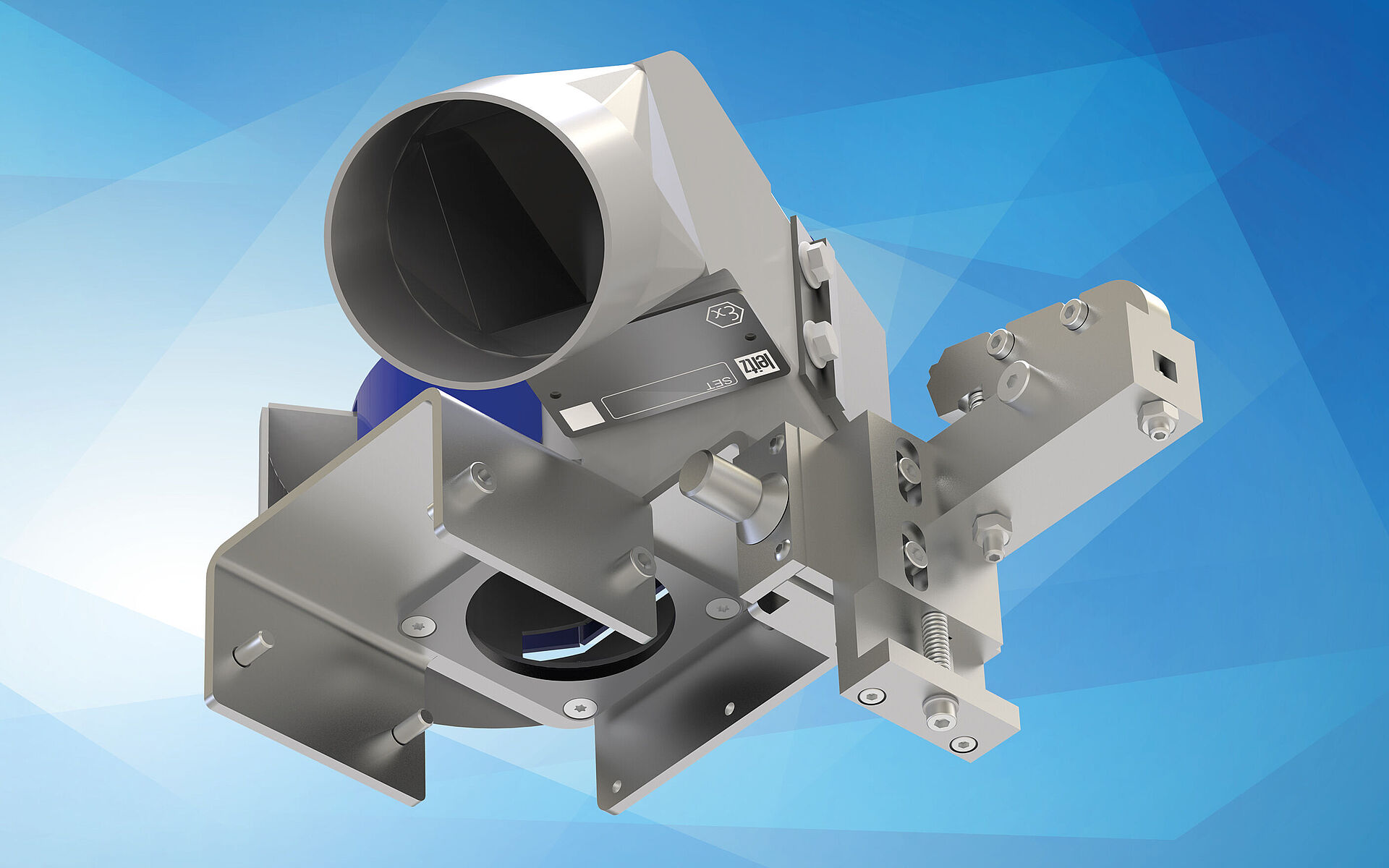

Jet nozzle

Jet nozzle

For with feed grooving to clean the groove and for special applications, a jet nozzle can be used as an air curtain instead of classic brushes.

LowNoise design

LowNoise design

A special external construction reduces the sound level by up to 5 dB(A).

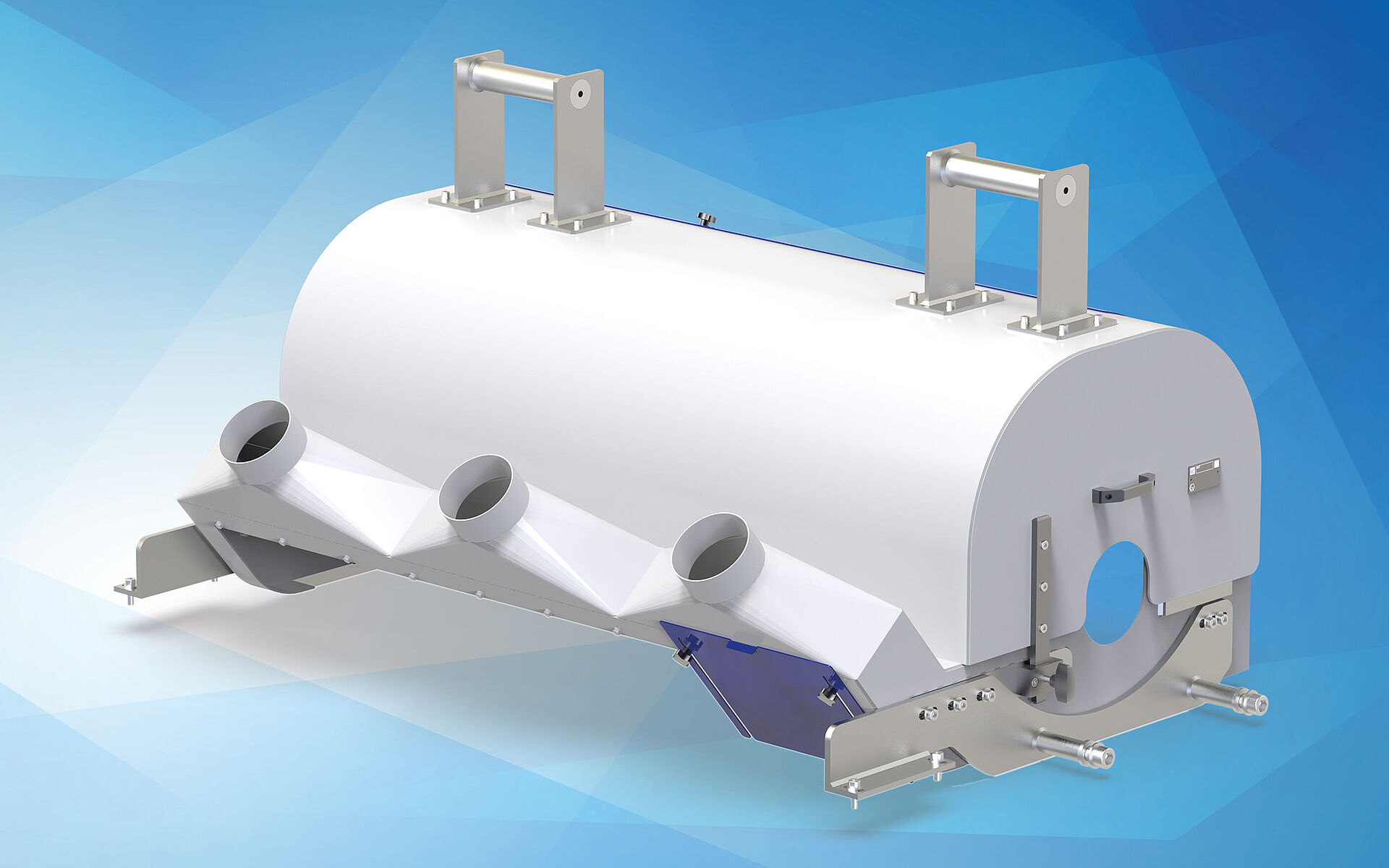

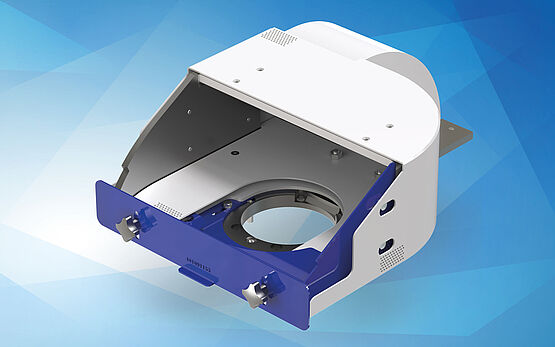

Lightweight construction

Lightweight construction

Lightweight extraction hoods can be used for large processing thicknesses and non-abrasive materials. An aluminium body and weight-reduced steel parts ensure a weight saving of around 30 %. The focus here is on ergonomics.

Special versions

Every project is individual. Thanks to Leitz‘s many years of experience in the construction of special hoods of all kinds, there is a suitable extraction hood for every requirement.