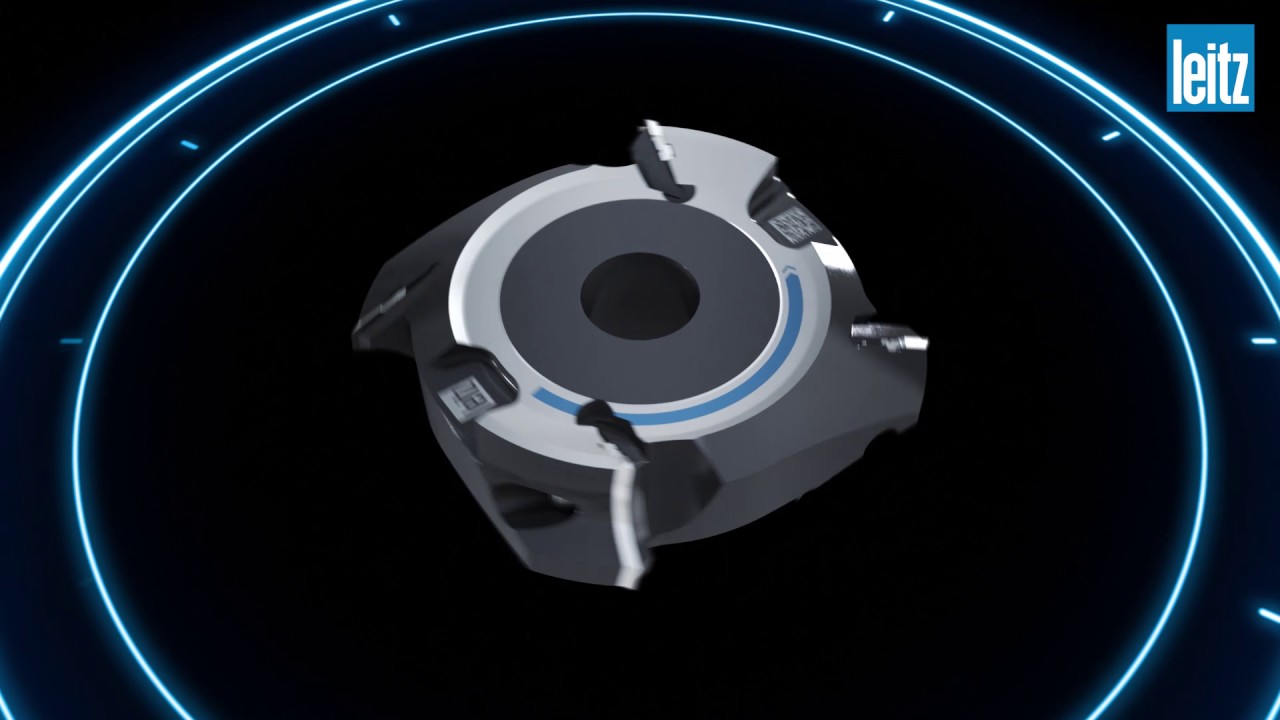

Leitz ProfilCut Q Diamond

The specialist for very abrasive materials

Abrasive materials or composite materials are not easy to machine due to their properties. Tool and cutting materials wear quickly, which in turn increases production costs. With the unique combination of an ultra-light aluminium tool body and resharpenable, profile and diameterconstant diamond changing knives, ProfilCut Q Diamond ensures efficient machining of abrasive materials. Precise and without loss of performance.

Long lifetime

Constant profile and diameter after sharpening

Lightweight construction for high-speed applications

Minimal set-up times

Easy handling

For cutting speeds (vc) up to 120 m/s

Includes Data Matrix Code or RFID chip for networked communication

5 times resharpenable

Especially suitable for systems with high part output

Preferably used in wood derived materials, plastics, aluminium as well as fibre or layered composites

Your benefits due to ...

Productivity & Efficiency

More parts in less time and with less effort

Productivity & Efficiency

More parts in less time and with less effort

20 times longer tool life through diamond cutting edges compared to TC

Reduce tool costs through six tool lives per knife

50 % higher feed rate by increasing the cutting speed to 120 m/s

Shorter set-up times through automatic knife positioning without setting devices

Reduced maintenance effort and machine downtime through higher life times

Maximum cost efficiency through the flexible use of disposable or resharpenable constant diameter systems

Reliability

Constant machining quality and user-friendliness

Reliability

Constant machining quality and user-friendliness

Profile and diameter constant after sharpening

Perfect precision repeatability after each knife service through precise, automatic knife clamping

Knives can be changed in the assembled tool set