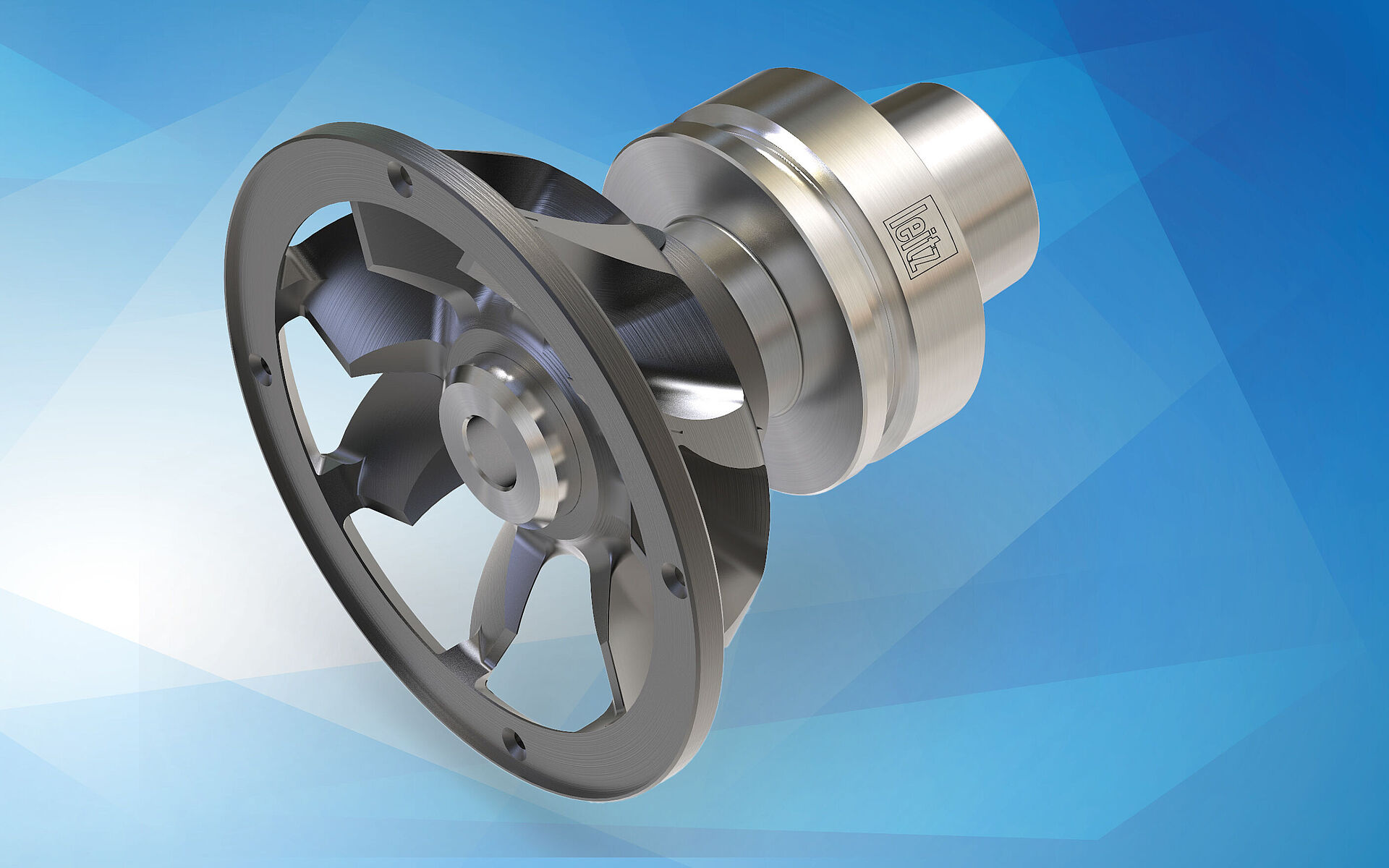

Leitz DFC® Turbine on ThermoGrip® shrink fit chuck

Reduces the dust load for people, machines and the environment

Nesting systems and machining centres are used throughout the furniture industry. The machining process generates a considerable amount of chips and dust that is not fully collected by the machine extraction system. The DFC®(Dust Flow Control) Turbine from Leitz was developed to direct chips and dust from the machining area towards the extraction system in the best possible way. This reduces the dust load for people, machines and the environment. The tool life is extended due to less double cutting and, in addition, energy consumption and cleaning effort are reduced.

0 %

Dust collection (max.)

0 mm

Distance (max.) to workpiece surface possible

0 %

Less energy requirement

YOUR BENEFITS

- Less dust pollution

- Increased tool life

- Less energy consumption

- Less cleaning effort

AT A GLANCE

- For CNC systems with HSK-F 63

- Best possible tool clamping due to ThermoGrip® shrink fit chuck

- External diameter 113 mm

- Low weight due to aluminium construction with hard coating

- Can be used up to 24.000 U/min

- Several panel thicknesses can be processed with one tool setting

Your benefits due to ...

Efficiency & Productivity

Optimal removal of dust and chips

Efficiency & Productivity

Optimal removal of dust and chips

- Significantly lower dust load and considerably less cleaning effort due to increased extraction effect

- Longer tool life due to less double cutting

- Chips are drawn towards the extraction unit and only need to be removed